Machined Parts Manufacturer

Make your product a reality and meet all your customers’ expectations. We use CNC milling, turning and other manufacturing techniques to turn your drawings into sophisticated parts.

About Us

Our Company

Based in Shenzhen, South China, Xtmachining provides precision CNC machining services to innovative companies around the world. We work with you at every stage of product development and have a team of highly trained technicians to help you turn your product ideas into reality. Whether you need a custom prototype or a small production run of up to 1,000+ units, we can serve you. We take quality control very seriously and get the job done perfectly every time. We will do whatever it takes to help you turn your product ideas into reality!

Our Capabilities

We perform complex milling and turning for prototypes, short-run and long-run production. By utilizing innovative machining techniques with state-of-the-art equipment and strict quality controls, our customers receive unparalleled machining services.

CNC Machining

CNC Milling

CNC Turning

Injection Molding

3D Printing

Sheet Metal Fabrication

From prototype to mass production

Prototype

We have developed the latest rapid prototyping technologies to meet your design challenges and will work with you to validate and improve your product ideas, functional testing and engineering verification. Include CNC prototyping, and etc.

Mass production

Even with our comprehensive on-demand production services, we guarantee superior precision and quality in all our products. Our advanced production processes ensure efficient productivity, allowing us to provide on-time delivery of your production parts.

Value-Added Services

Product Development

Our CNC machining experts can help you design products and parts that are cost-effective and manufacturable in low volumes.

Prototype Castings

Explore and learn more about prototype metal castings. Many of our customers use prototype castings as production parts.

On-Demand

Low-volume manufacturing at your fingertips. We offer product design assistance, development assistance, prototyping, and production.

Heat Tempering

Let our experienced engineers recommend a specific heat treatment process for your castings to ensure your project is a success!

How to work with us

1. Send your quotation

Please provide us with your drawing file in 3D format or PDF format.

2. Provide you with the best solution

Evaluate the drawing details with our professional engineers and select the best solution for the workpiece based on your priorities (price, quality and delivery time).

3. Sampling and confirm your order

The sampling project can be started after the review and agreement of both parties; the production plan will be started immediately after receiving the order confirmed based on the sample. Regular and timely update of your order status.

4. On-time delivery

We provide strict quality assurance procedures, from material certificates to production monitoring records to inspection quality reports, each step meets ISO standards and guarantees the delivery time of the order.

Materials

By understanding the unique properties of each material, we can select the ideal material to ensure project success. We provide batch and lot traceability that meets our customers’ regulatory requirements.

Metals

Plastics

Rubber

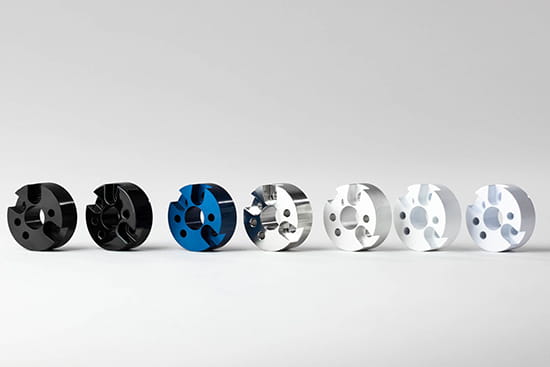

Full range of surface finishing services

Whatever your needs, our versatile CNC machine shop is ready for your next project. We manufacture precision parts using multi-axis CNC milling and turning, wire EDM, CAD/CAM, CMM inspection and 3D printing. In addition to this suite of machining processes, we also offer a range of value-added services including anodizing, sandblasting, passivation, heat treating, powder coating, deburring and more. This allows us to meet a wide range of project requirements quickly and efficiently.

Request a Quote

Do you need a quote for your high-precision part? Contact us now by phone, email, or through our contact form.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…