CNC Turning Services

Providing you with the best CNC lathe services and custom CNC turned parts solutions. Efficient production, fast delivery and competitive prices.

Full range of CNC turning solutions

Xtmachining focuses on completing the entire process from design to production on time and within budget, but we also help customers turn ideas into fully realized products. Our experts will work with you to develop concepts, select the right materials and start full production. We can provide rework services for parts in finished, semi-finished or rough state.

We integrate multiple aspects of production under one roof, eliminating the need to move work-in-process parts between supply chain partners. We take on the hassle, saving you time and money. We treat every job with the concept of quality first. All processes follow a strict quality management system. Materials are purchased from reputable suppliers and verified for compliance upon arrival. Sophisticated testing and inspection equipment ensures that every part produced exceeds applicable industry standards or customer specifications. All orders are reviewed for accuracy before shipment.

Our Advanced Equipment & Capabilities

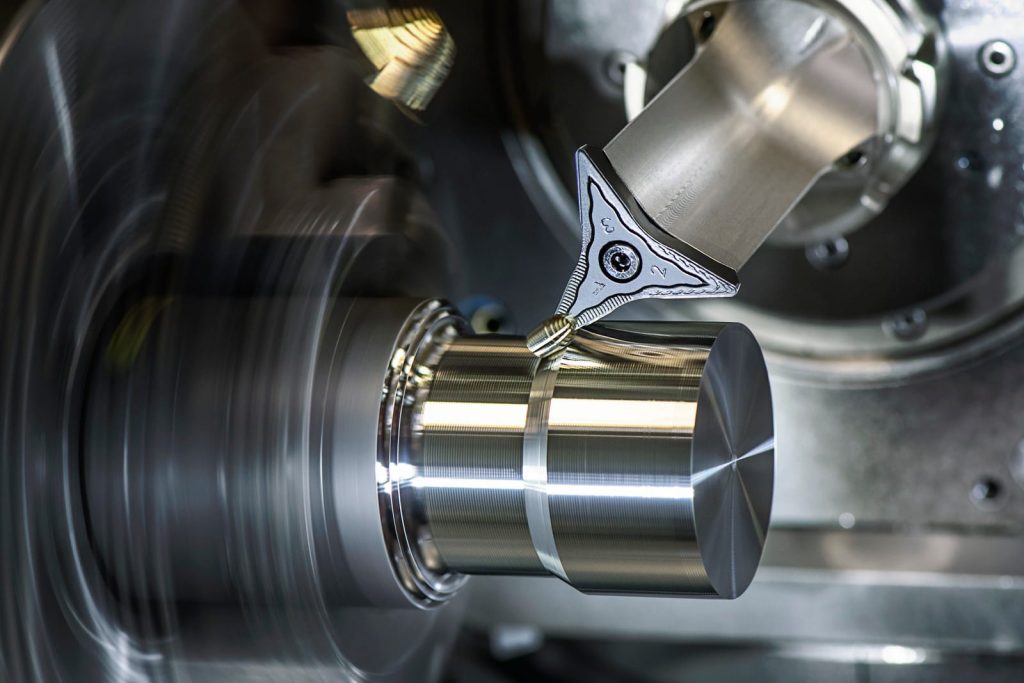

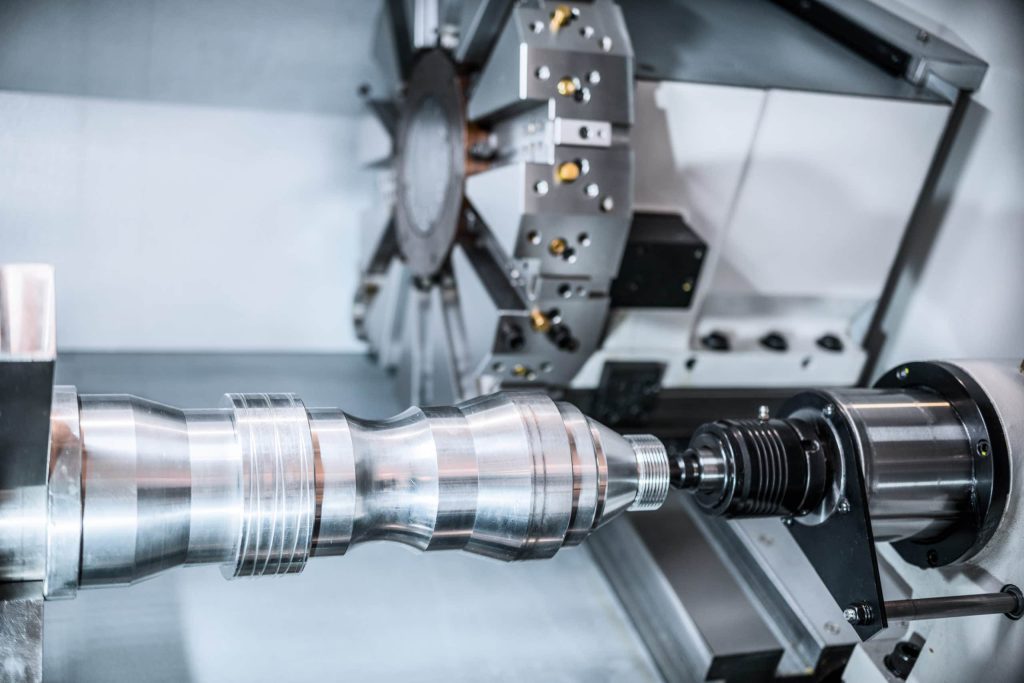

Our professional CNC machinists and tool and die makers use state-of-the-art equipment to meet or exceed our customers’ high quality standards, including the most complex parts. As a result, we can produce parts with close tolerances (+/- .001 inch or better) on parts up to 10 inches in diameter. We continue to invest in the latest equipment. As a result, our customers receive the lowest part cost, the highest quality, and the best delivery. In addition to CNC turning, we also offer additional services such as CNC milling and wire cutting. We are a full-service tool and die shop. Our talented and experienced tool and die making engineers and machinists provide a variety of services. In our state-of-the-art facility, we continue to invest in the latest equipment and software. As a result, our customers receive the lowest part cost, the highest quality, and on-time delivery.

CNC Turning Lathe Types

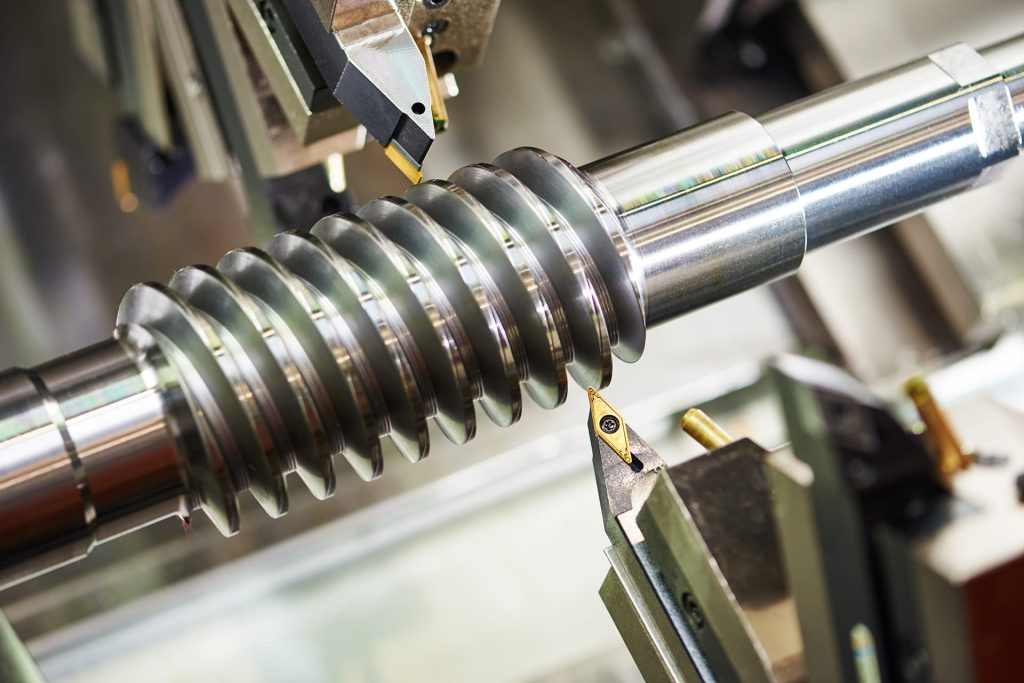

Xtmachining has CNC lathes with a variety of capabilities. We can provide the highest precision CNC turning services for machine parts and components. We can also provide engineering, milling and cleaning services for your metal parts.

CNC Vertical Turning

CNC Horizontal Turning

Tolerance Standards for CNC Turning

We utilize CNC lathes for complex machining projects that require tight tolerance specifications up to ±0.005 inches – accurate to a few thousandths of an inch! Our standards for metals follow ISO 2768-m, while plastics adhere to the requirements set forth in ISO 2768-c.

We help you make custom parts better and faster

We can help you complete all the important and complex work of custom product prototyping and manufacturing, from initial design to small batch production, post-processing, logistics, etc. Xtmachining is committed to speeding up your prototyping and manufacturing process and reducing costs. Whether it is a one-off prototype or a batch production of thousands, we can help you.

Complete In-House Services

Our team of experts is dedicated to providing high-quality machining services to meet your specific needs. With state-of-the-art equipment and a commitment to precision, we deliver exceptional results every time. Whether you need a prototype, low-volume production or large-scale production, we ensure a comprehensive and consistent process to complete your part. Partner with us for reliable, efficient machining solutions.

Design for Manufacturing (DFM)

We offer DFM services to help speed part production, streamline production processes and reduce costs. Our engineering team will work with you as needed to optimize your design for manufacturability without changing the fit, form or function of the turned part.

In-House Tool Shop

We design, manufacture and maintain all of our tooling for CNC turning projects. We monitor every step of the process to ensure precision and quality of the finished part. All tooling is custom-made for each project, and we will maintain and service your tooling for the life of your project. By bringing additional services in-house, we can save your project time and money, shorten your supply chain and reduce the potential for problems or oversights.

Our Quality Control Management

The company has a strict quality control system to ensure that all products meet customer requirements. Before delivery, we conduct comprehensive testing on our customers’ products to ensure that the products meet specifications, including dimensional accuracy, surface finish, hardness and precision. We utilize a variety of advanced measuring equipment to verify key dimensions to ensure that every product we produce is of the highest quality. Our commitment to quality ensures that every customer receives products on time, with the highest accuracy and in accordance with their requirements.

Material Options

Our CNC turning services can be tailored to your needs and process a wide variety of materials. If your project requires a material not on the list, let us know! We can accommodate other material requests, but may require more time to quote when sourcing materials.

Metal & Alloy Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

Plastic Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

Surface Finishes

We offer a wide variety of high-quality surface finishes, each with unique properties to meet your specific application needs.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Polishing (Ra 0.8μm / Ra 32μin or better)

- Bead Blasting

- Tumbled

- Bead blasted

- Anodized type

- Black Oxide

- Powder Coated

- Chromate Conversion Coating

- Plating

- DLC (Diamond-Like Carbon) Coating

Let us provide you with a quote for your next project

We can quote your project using either traditional CAD files or PDF files, fill out our simple form and we will contact you with a competitive quote.

What is CNC Turning?

CNC turning is a special form of precision machining in which the cutting tool removes material by contacting the rotating workpiece. The machine’s motion is controlled by computer instructions, allowing for extremely high accuracy and repeatability. Turning differs from CNC milling, where the cutting tool rotates and is aimed at the usually stationary workpiece from multiple angles. Because CNC turning involves rotating the workpiece in a chuck, it is often used to create circular or tubular shapes, achieving more precise circular surfaces than CNC milling or other processes. The tooling used by a CNC lathe is mounted on a turret. This component is programmed to make certain movements and remove material from the raw material until the desired 3D model is formed. Like CNC milling, CNC turning can be used to quickly create prototypes or end-use parts.

Features of CNC machining

Compared with traditional manual machining, CNC machine tools, as the core part of CNC lathe services, are popular because of their unique features and unparalleled advantages:

- High precision and high quality

- Constant quality standards are maintained throughout the manufacturing process

- Multi-axis linkage operation is possible

- Customized CNC turning parts with complex shapes can be processed

- Part design can be easily changed by simply updating the CNC program

- High efficiency (3-5 times more efficient than traditional machine tools)

- Automation reduces labor and time consumption

Difference between CNC Milling and Turning

CNC milling and CNC turning allow users to create patterns and add details to metal that cannot be done by hand. CNC milling uses commands, codes that are programmed into a computer and set to run. The milling machine then drills and rotates along an axis to cut the material to the dimensions entered into the computer. Computer programming allows the machine to make precise cuts, and users can manually override the CNC machine to slow or speed up the process.

In contrast, CNC turning uses a computer-controlled machine to create different end products. The process uses a single-point cutting tool that is inserted parallel to the material to be cut. The material rotates at varying speeds and the tool cuts across to create a cylindrical cut with precise measurements. It is used to create round or tubular portions from larger blocks of material. It is an automated process that adjusts speeds for greater precision than turning a lathe manually.

If you are unsure whether your part should be produced by turning or milling, contact our team of engineers and we will take a closer look at the project and recommend the best process for your project.

Industries We Serve

We specialize in providing customers with high-precision, high-efficiency CNC turning solutions. Whether it is a simple geometry or a complex part, our advanced equipment and professional team ensure that each product meets the highest quality standards. Our CNC turning services are widely used in various industries and can help you achieve excellent product performance and fast market response. Choose us to make your parts processing more accurate and reliable.

Learn how Xtmachining can serve your next CNC turning project

Your one-stop shop for custom CNC turned parts. We deliver quality parts on time and at competitive prices. Request a quote today to learn how we can meet your machining needs.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…