Sheet Metal Fabrication Services

Are you looking for a reliable sheet metal rapid prototyping and production partner? We can help. Get an online quote within hours and a free analysis of quality parts within days.

Professional Sheet Metal Fabrication Service Provider

Our company has a team of professional designers and technical engineers who specialize in sheet metal fabrication and have over a decade of experience in the metal fabrication industry. As a result, we offer a range of custom solutions for sheet metal production. We treat each order as an individual project, providing consultation, part design advice, production planning, and then CAD creation as well as sheet metal part machining, surface finishing and assembly services. Regardless of the scope of your project, Xtmachining’s manufacturing services cover all aspects of contract metal fabrication services, ensuring that each customer’s product requirements are not only met, but exceeded. With our turnkey capabilities, we are able to handle large-scale production as well as more specialized, low-volume projects with unwavering precision and efficiency. As a result, you can rest assured that the custom solutions we offer you can help you meet your turnaround time or any other critical project deadline in a short period of time, allowing you to meet tight deadlines with ease.

Professional Sheet Metal Fabrication

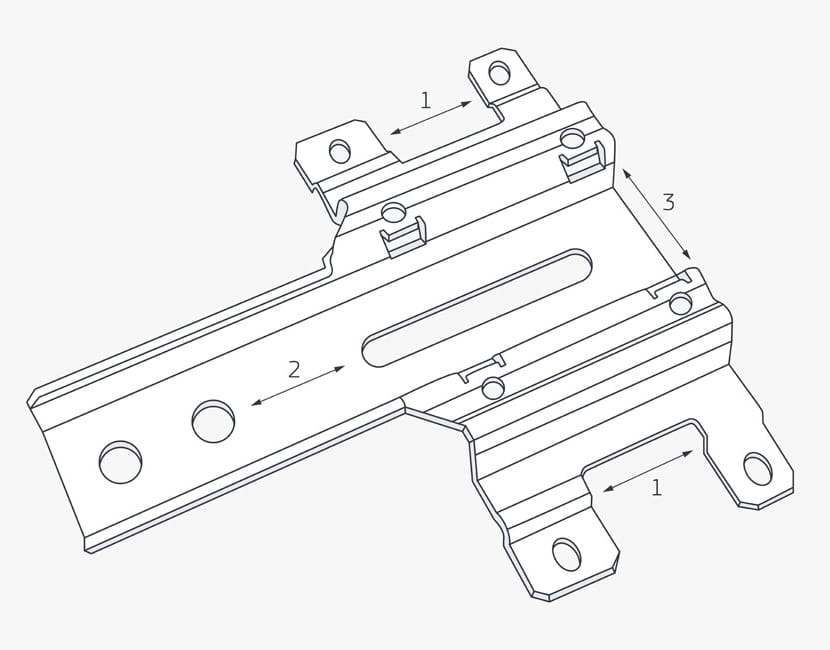

As an experienced sheet metal product manufacturer. We have the precise equipment to produce and assemble custom sheet metal components. This includes manufacturing the simplest parts and the most complex assemblies in large or small batches. Our extensive sheet metal fabrication capabilities allow us to provide effective manufacturing solutions that meet your exact needs rather than providing limited options. When manufacturing custom products, our machines are compatible with many different types of metals, sheet lengths, and thicknesses. Xtmachining is able to produce large or small batches of these custom laser cut sheet metal products. Typically, the manufactured sheet metal parts can be used for prototyping or large-scale production operations.

Our Capabilities

Our equipment is capable of running coils or cutting blanks from sheet stock for high volume projects. We typically process components ranging from 0.030” to 0.070” thick and approximately 10” x 18” in size with a dimensional tolerance of ±0.005”, but are capable of handling a wide range of material specifications from 0.008” to 0.188” and can process sheet metal up to 4’ x 12’.

We specialize in providing our customers with a comprehensive single fabrication, machining, and finishing service. Because we perform all of our services in-house, we are able to not only streamline our customers’ supply chain, but also optimize manufacturing operations by working with our customers to explore different fabrication methods to find the best solution for their specific application.

Ready to discuss your metal fabrication service needs?

From conceptualization to realization, Xtmachining is here to help you with sheet metal fabrication. Contact us today to discuss your next project and get a free estimate.

Custom Sheet Metal Fabrication Solutions

We can support one-offs, batch production, welding and assembly, and stock based on your requirements. Xtmachining’s engineers can take on challenging and complex jobs, whether it’s complex part geometry, specialized materials, extremely tight tolerances, or specialized finishing.

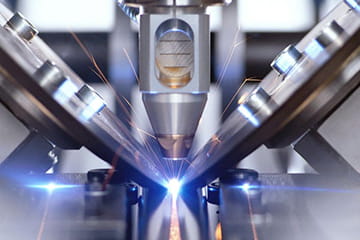

Laser Cutting

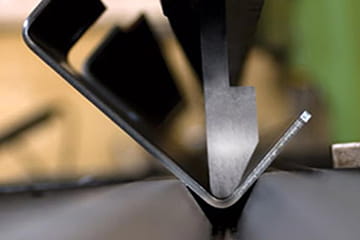

Sheet Metal Bending

Tube Bending & Fabrication

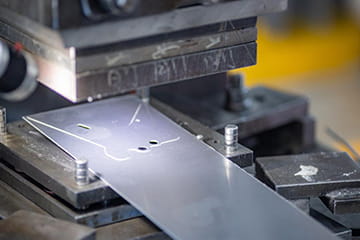

Metal Stamping

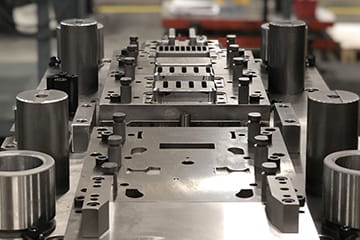

Stamping Dies

Welding & Assembly

Material Options

Sheet metal fabrication processes accommodate a wide range of materials, each suitable for different part and production requirements. Understanding the characteristics of potential material choices is critical to determining the correct material for a specific project. Below we have outlined the materials we process.

- Aluminum

- Stainless Steel

- Cold Rolled Steel

- Hot Rolled Steel

- Brass

- Copper

- Titanium

- Galvanized

- Galvannealed

- Nickel Alloys

- Inconel

- Monel

Surface Finishing Options

The surface finish of your sheet metal parts depends on your design. We offer many types of sheet metal part finishes to cover and protect the metal, ensuring it lasts and lasts.

- Heat Treating

- Plating

- Finishing

- Powder Coating

- Assembly

- Kitting

- Painting

- Tooling

- Anodizing

- Annealing

- Number Stamping (Rubber Ink and Metal)

- E-Coat

- Stress Relieving

- Vibratory Bowl Deburring

- Tumbling

- Assembly

- Packaging

- Rivet

- Inserting

- Welding

What can we do for you now?

To learn more about our precision sheet metal fabrication capabilities or to work with us on your next project, contact us or request a quote today. Our experts will answer and address any questions or concerns you may have.

What is Sheet Metal Fabrication and How Does It Work?

Sheet metal fabrication (or metalworking) is a process that creates metal parts, components, and structures from raw materials. Typically, the process forms steel and aluminum sheets into metal components and desired shapes through a range of techniques, including cutting, stamping, folding, and assembly.

Sheet metal fabrication is a versatile and valuable process that involves creating metal structures and components by cutting, bending, and assembling various types of sheet metal. The process begins with selecting the appropriate sheet metal, such as stainless steel or aluminum, based on factors such as corrosion resistance, strength requirements, and aesthetics. Once the sheet metal is selected, it is cut using modern equipment such as laser cutters or water jet cutters to achieve precise dimensions. After cutting, the sheet metal is formed and shaped through various methods such as bending, rolling, or folding to create the desired structure or component. To ensure the strength and durability of the fabricated piece, different sheet metal components may be securely joined together using welding techniques such as gas tungsten arc welding or metal inert gas welding. Finally, the fabricated piece may undergo additional processes such as powder coating or galvanizing for enhanced durability and customization.

Advantages of Sheet Metal Production

- Sheet metal design options are very flexible. Customers can express a need for specific features, and sheet metal materials allow for many different solutions.

- It is possible to go from a single prototype to mass production. Modern production methods such as 3D printing offer fast lead times that fit the needs of prototyping perfectly. However, these methods are limited to prototyping.

- Sheet metal manufacturing processes lend themselves to a gradual transition from prototyping to mass production. Prototyping sets a baseline and sets expectations for mass production by establishing the required infrastructure.

Sheet Metal Design Guidelines and Tolerances

- Minimum Bend: 1 Times Sheet Metal Thickness

- Minimum Hole to Edge Distance: 2 Times Sheet Metal Thickness

- Minimum Hole to Hole Distance: 6 Times Sheet Metal Thickness

- Minimum Bend Edge to Hole Distance: 6 Times Sheet Metal Thickness

- Minimum Feature to Countersink Distance: 8 Times Sheet Metal Thickness

- Minimum Countersink Depth: 1 Times Sheet Metal Thickness

- Relief Cuts: 1 Times Sheet Metal Thickness

- Cutting Feature: ± .00787’’ (0.2 mm)

- Bend Angle: ± 1.0°

- Bend to Edge: +/- 0.010” (0.254mm)

Industries we serve

As an important metal processing product, sheet metal parts have a wide range of working principles and applications, covering almost every industry and field. Through our sheet metal processing and manufacturing OEM services, we can meet the needs of different industries and provide convenience and flexibility for the manufacturing of various products.

Tell us about your sheet metal parts processing needs

Whatever questions you may have about your sheet metal project, just ask. We will log every inquiry and try to respond within one hour. Then, our team will work together to resolve your request.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…