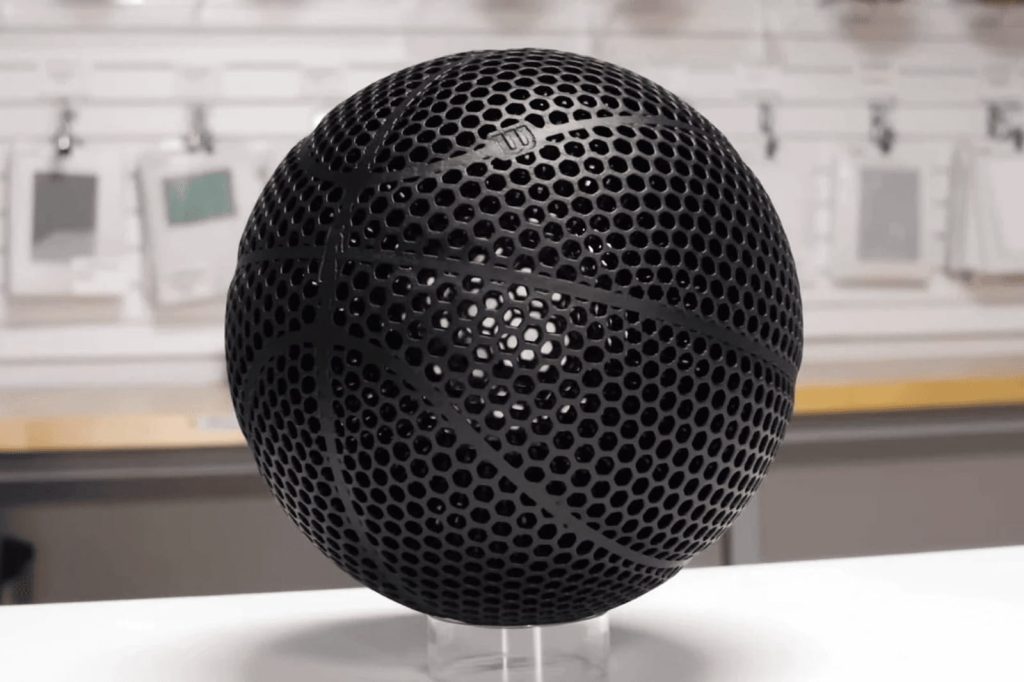

3D Printing Services

Our 3D printing services offer advanced additive manufacturing technology that reduces production costs and time. Whether you require rapid prototyping or custom 3D printed parts, our state-of-the-art technology delivers high-quality results.

Professional 3D Printed Parts Supplier

Xtmachining offers a wide range of 3D printing services and has the right solution for your project. Whether your business needs parts, prototypes or consumer goods, we can add value throughout the product development and production process.

Our cutting-edge 3D printing services can meet the various needs of our customers around the world. With state-of-the-art technology and expertise, we provide fast and precise additive manufacturing solutions for prototyping, tooling and end-use production. Our wide range of materials, including plastics, metals and composites, ensures versatility and high-quality results for projects in a wide range of industries. From concept to finished product, Xtmachining provides excellent service, innovation and reliability to turn your ideas into reality with speed and precision.

3D Printing Solutions

3D printing allows for rapid design iterations, which can reduce time to market without sacrificing component quality. It also has the benefit of reducing material waste and tooling costs. Xtmachining’s professional 3D printing services ensure an effective turnkey solution for precision products and parts. Our team is experienced in working with a wide range of materials and multiple 3D printing technologies, working closely with customers to select the best combination of materials and production methods to deliver high-quality results and optimal versatility while helping you reduce turnaround time. So, whether it’s an initial prototype or an end-use part, leverage cost-effective 3D printing to transform the way new products are brought to market.

Rapid Prototyping

Prototyping is an essential part of product development. Do you need parts as quickly as possible to validate your project? 3D printing is the shortest path from your idea to a functional prototype in your hands. 3D printing can be a powerful ally in the early stages of your product development.

Contract Manufacturing

Are you looking for a reliable partner that can provide you with the parts you need, when you need them, in the quantities you need? From 1 to 10,000 units, this digital manufacturing technology can help you rethink production, adding more freedom and flexibility without sacrificing quality.

On-Demand Manufacturing

With our On-Demand Manufacturing service, you get the exact quantity of parts you need, when you need them. Use additive manufacturing and adjust production to demand. Using additive manufacturing allows you to avoid minimum order quantities, perfect for limited editions or mass production.

Get started with your project with a free quote

Consult our experts to help us provide you with the perfect custom design you need to complete your project. No matter how complex or challenging your idea may seem, we have the expertise to help you turn it into reality.

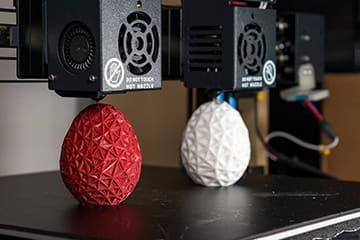

Our 3D Printing and Additive Manufacturing Technology Types

To ensure your project is successful, we have a wide range of 3D printing technologies. Xtmachining’s 3D printing services provide rapid prototyping and high-volume production. Our technologies are designed to efficiently produce multi-component and multi-material parts for projects that require an agile development cycle. Able to create complex designs and geometries with high precision and consistency.

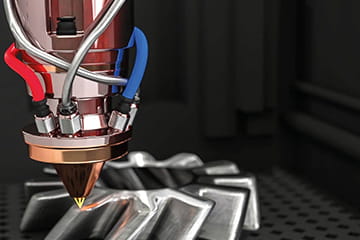

Metal 3D Printing

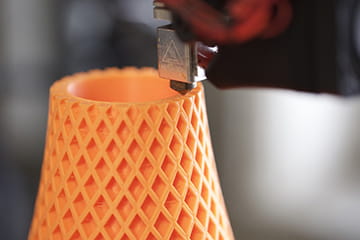

Fused Deposition Modeling (FDM)

Selective Laser Sintering (SLS)

Multi Jet Fusion (MJF)

Stereolithography (SLA)

Carbon Digital Light Synthesis (DLS)

PolyJet

Direct Metal Laser Sintering (DMLS)

Metal Binder Jetting (MBJ)

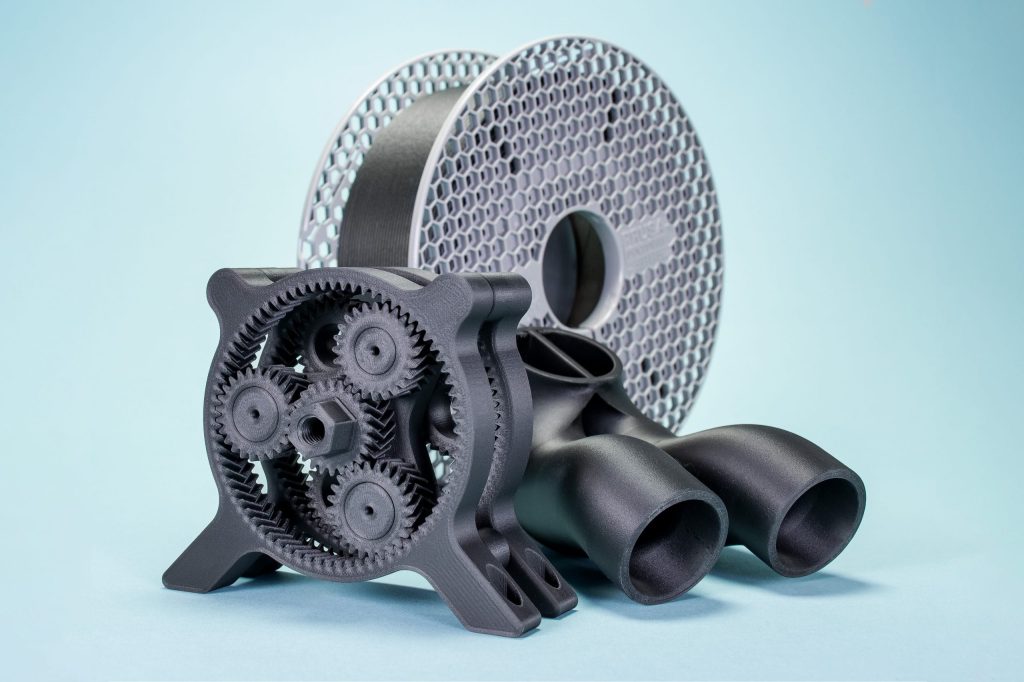

3D Printing Material Options

Our material selection includes plastic and metal options for a wide range of industrial custom 3D printing projects. If you have unique material requirements, please contact our team of engineers. We are committed to sourcing the materials you need.

Metal Materials

- Titanium Alloy

- Aluminum Alloy

- Stainless Steel

- Tool Steel

- High-Temperature

- Nickel Alloy

Polymer Materials

- Nylon

- Nylon GF (Glass-Filled)

- SLA Resin

- TPU (Thermoplastic

- Polyurethane)

- PLA (Polylactic Acid)

Post-processing for 3D printing

Surface treatment can serve both functional and aesthetic purposes. Post-processing can enhance the appearance and functionality of 3D printed parts, making them smooth, colorful, or more durable. Post-processing is great for visible or functional components, but may not be necessary for rough prototypes or internal parts where aesthetics are not a primary consideration.

- Polishing

- Anodizing

- Painting

- Zinc Plating

- Chromate Conversion Coating

- Passivation

- Powder Coating

- Sandblasting

- Nickel Plating

- Electropolishing

Ready to start 3D printed prototyping?

Xtmachining’s 3D printing services are tailored to the needs of modern manufacturing, providing comprehensive solutions for the efficient production of detailed, complex and multi-material products. Contact us today for a quote.

What is 3D printing?

3D printing is an additive manufacturing process that joins materials together to create objects based on 3D model data (CAD). Typically, 3D printing is a layer-by-layer process that involves adding material layer by layer until the final object is formed. 3D printing processes can create objects from plastics, photopolymers, reactive polymers, composites, metals, glass, and other materials.

Advantages of 3D Printing

- Rapid Prototyping: 3D printing enables fast and cost-effective prototyping, speeding up product development cycles and allowing iterative design improvements.

- Design Flexibility: 3D printing makes it easy to produce complex geometries and custom designs, providing unparalleled design freedom and opportunities for innovation.

Low-Volume, Cost-Effective Production: For low-volume or custom production, 3D printing is more cost-effective than traditional manufacturing methods because it eliminates the need for expensive tooling and setup. - Reduce Material Waste: Unlike subtractive manufacturing processes that create a lot of waste by cutting material, 3D printing adds material only where it is needed, minimizing waste and reducing material costs.

What parts are suitable for 3D printing?

Most industries require parts that are well suited to 3D printing, especially for low-volume production and prototyping. While 3D printed parts take longer to make than injection molding, the elimination of molds and the use of additive manufacturing means minimal waste and no tooling fees, which can be prohibitively expensive with other production methods. 3D printing is ideal for printing mechanical fixtures such as brackets, mounts, and housings. Even washers and large bolts can be printed if the plastic part is designed thick enough, but more robust parts require metal powder 3D printing.

While CNC and injection molding can also be used to make custom parts, their high setup costs make them suitable only for large-scale production, so 3D printing offers engineers an inexpensive option for custom part manufacturing services. 3D printing services are also ideal for prototype testing of products that require only a few hundred units, a specific type of housing bracket or accessory, or a component or product for a highly specialized industry with a low production volume.

Industries We Serve

With our additive manufacturing facilities, we offer professional, customized industrial 3D printing services that are perfectly suited to your needs. As your engineering printing solutions partner, we develop high-precision plastic parts for demanding applications across a wide range of industries.

Ready to get started?

Whether you need rapid prototyping or custom 3D printed parts, our state-of-the-art technology delivers high-quality results. Our team of engineers is ready to help you turn your ideas into reality. Get a quote now.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…