Automotive

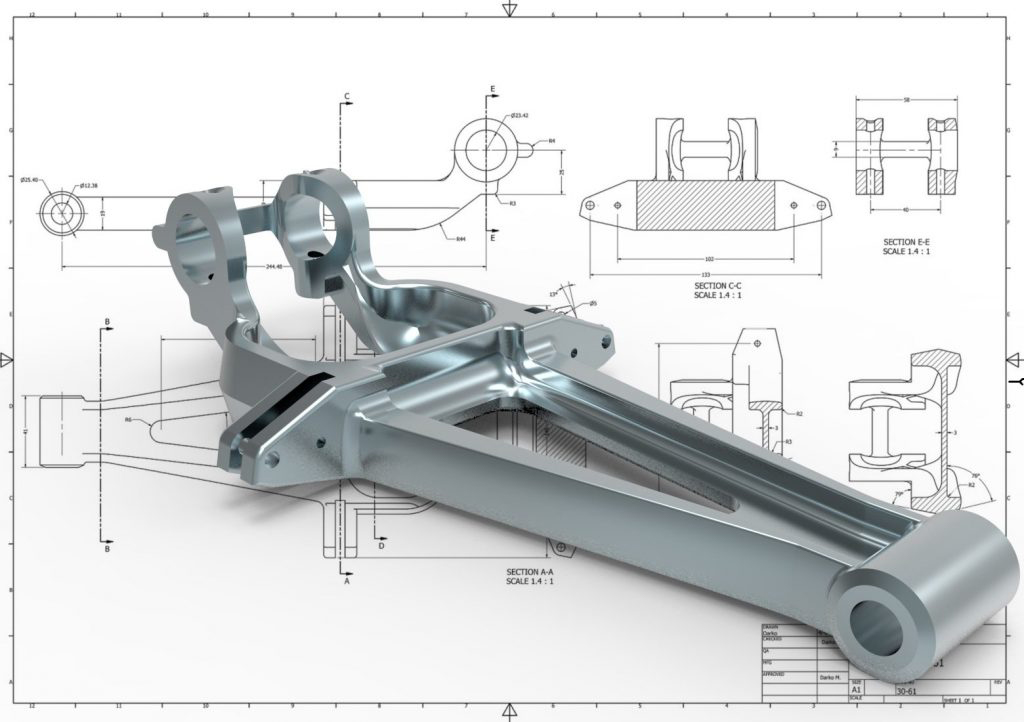

In the automotive industry, precision machined parts are essential to produce a high-quality end product. A car is a complex structure made up of many parts. Xtmachining’s team of engineers have the automotive industry knowledge to ensure that the manufactured parts meet customer requirements. Our team will work with customers to analyze drawings and provide advice on automotive industry part design.

Automotive Parts Manufacturers

In the rapidly evolving automotive industry, where technological advancement meets sustainability, our company is committed to pioneering automotive parts customization technologies to meet manufacturers’ current and long-term needs. We specialize in innovative solutions and focus on improving component production efficiency, reliability, and functionality. We use material science and the latest manufacturing technologies to provide high-quality parts to the automotive industry. Our passion for excellence in the automotive industry drives our approach to provide manufacturers with the innovation they need to meet the diverse needs of today’s market.

Automotive Parts Manufacturing Solutions

If you are looking for a manufacturing partner that offers deep expertise, speed and adaptability in the automotive industry, Xtmachining can help you accelerate your new product innovation, prototyping and production plans. Our team will work with you every step of the way and provide you with advice and expertise in:

- Develop concept refinement automotive part prototypes.

- Optimize part design, material selection and production processes for the best results.

- We also offer solutions for transitional production, short-run production or full production.

How can we help you with your automotive parts needs?

From the moment you contact us, you will work with an engineer who will work closely with you to fully understand your project needs. And take a hands-on, personalized approach to help you troubleshoot potential manufacturability issues during the review and analysis process. We will help you plan the best manufacturing solution for your project through part design review, material selection recommendations, tolerance review, etc.; and provide solutions with competitive costs. Our wide range of manufacturing technologies range from CNC machining and metal forming to injection molding and the latest additive technologies. We will guide you to find the solution that best suits your needs and the environment your parts must operate in.

Contact us now to get customized automotive parts solutions

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Our Capabilities for the Automotive Industry

At Xtmachining, we provide automotive innovators and engineers with rapid prototypes and parts made to their specifications for even the most complex or unique designs. If you need a reliable, cost-effective partner, contact us today.

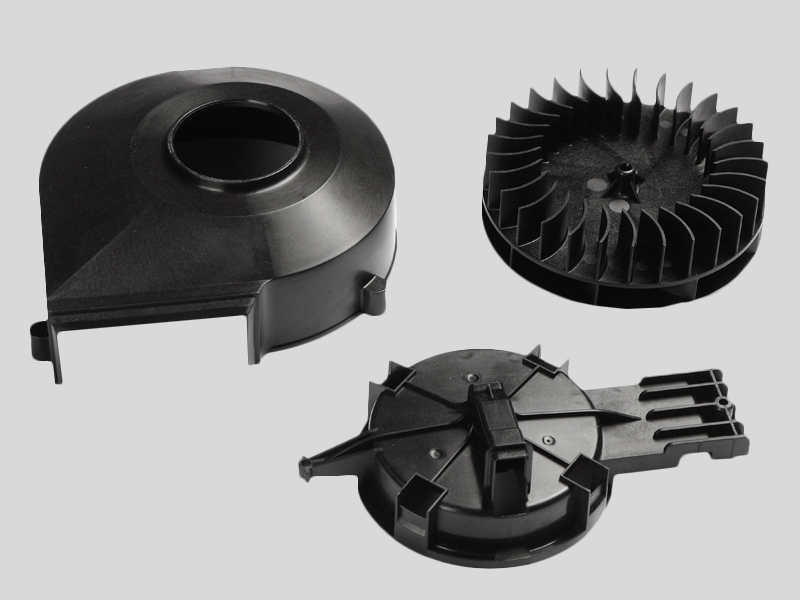

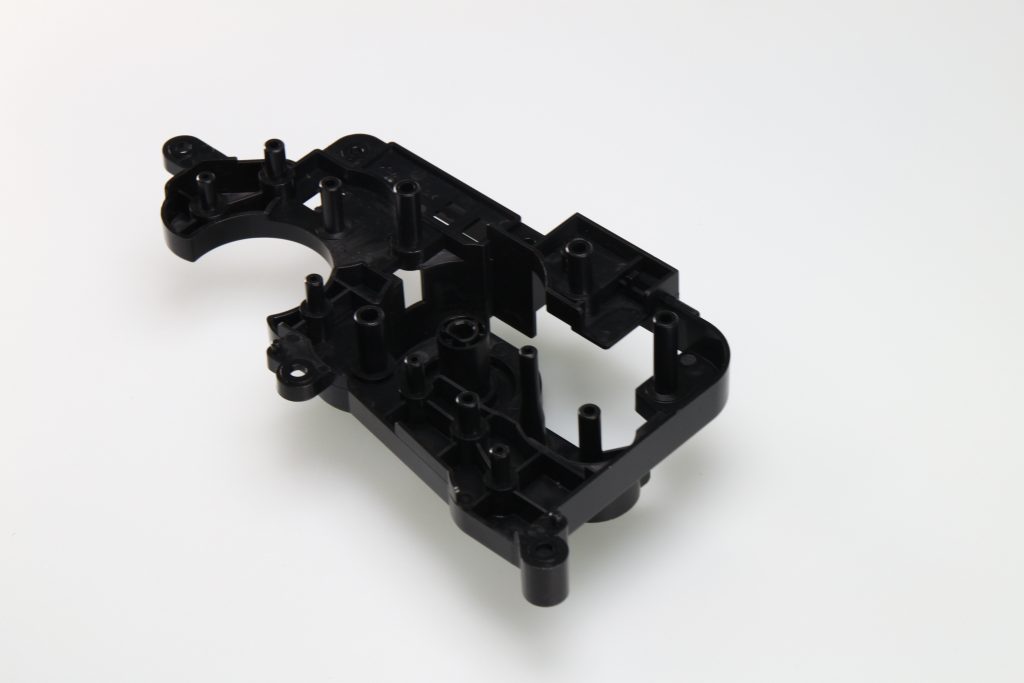

Plastic Injection Molding

CNC Machining

3D Printing

Rapid Prototyping

Sheet Metal Production

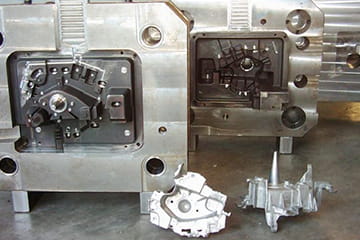

Die Casting

High Precision and Tight Tolerances

For each auto parts processing project, we adhere to strict tolerances, and the dimensional tolerance can reach ±0.0004″ (0.01mm). Professional engineers and quality inspection teams follow up to ensure part accuracy.

Supply Chain and Manufacturing Solutions

We recognize the importance of agile supply chain solutions in the automotive industry. Our adaptable solutions can help navigate the complexity of the supply chain, helping automakers to minimize disruptions and remain cost-effective. Our goal is to help OEMs manage production costs and promote product differentiation in a competitive market.

What Kind Of Automotive Parts Can We Make?

Xtmachining’s highly skilled engineering department is able to use design manufacturing knowledge to ensure the high quality of automotive plastic parts. With our expertise, we can guarantee that quality parts are manufactured to meet your needs in the shortest possible delivery time.

- Engine parts: High-precision parts such as pistons, cylinder heads, crankshafts, connecting rods, etc.

- Transmission system parts: Key components such as gears, gearbox housings, drive shafts, differentials, etc.

- Chassis parts: Suspension system parts, steering system parts, axles, brake discs, etc.

- Body structure parts: Sheet metal parts such as doors, hoods, bumpers, side panels, etc.

- Interior part: Precision components such as center consoles, dashboards, seat frames, decorative strips, etc.

- Electronic parts: Electronic control system parts such as sensor housings, connectors, radiators, etc.

- Exhaust system parts: High-temperature resistant parts such as exhaust pipes, mufflers, catalytic converters, etc.

- Fuel system parts: Key components such as fuel pumps, fuel injectors, fuel tanks, and fuel pipes.

Material Options

Depending on the part you need to manufacture and the design requirements, you can choose from different types of materials: metal, plastic and silicone. If the material you want is not available, please contact our team to source it for you.

Metals

- Stainless steel

- Aluminum

- Titanium

- Copper

- Magnesium

- Bronze

- Carbon steel

- HT steel 4140

- Zamac

Plastics

- Acrylic

- ABS

- PC

- PPS

- PS

- Silicone rubber

- Urethane

- Epoxy

Automotive Parts Surface Treatment

A variety of surface treatment options are available to provide your automotive prototype parts with a unique surface finish to meet the aesthetic and corrosion resistance needs of the parts. Professional surface treatment process engineers select the appropriate surface treatment based on your automotive part material and application. The following are common surface treatments:

- Powder Coating

- Painting

- Polishing

- Passivation

- Water Transfer Printing

- Laser Carving

- Silk Screen

- CNC Machining

- Etching

- Brushed

- As-Machined Finish

- Multi-Color Anodized

- Hard Anodizing

- Sandblasting +

- Anodizing

- Iron black Anodizing

- Chrome Plating

- Blue Zinc Plated

- PVD

- Electrophoresis

- Nickel Plating

Why do we need automotive prototyping?

The automotive industry is a complex and large industry. Faced with market pressure and the improvement of people’s aesthetic level, frequent design iterations and new design development are required. However, the automotive design and development cycle is a long process, so fast and efficient prototyping is a must. Automotive prototyping is an essential and important step in the verification process between initial product design and final production run. The automotive prototyping process will help the design team figure out how to make the new design attractive to consumers and prove its value, how to communicate ideas and iterative designs with stakeholders and project teams faster and more effectively, and how to verify and test functions and evaluate whether the part manufacturing process is reasonable.

Get an accurate quote for your next project

No matter what type of automotive manufacturing service you need, we can provide a one-stop solution from prototype to mass production. Whether your project is complex or simple, metal or plastic, you will get an accurate quote within 6 hours.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…