Oil and Gas

Xtmachining specializes in short-run, high-mix production of highly customized parts. We offer a comprehensive portfolio of solutions to help you simplify parts procurement.

Custom Parts Manufacturer for the Oil and Gas Industry

We have extensive experience in custom parts manufacturing for the Oil and Gas industry. Our team, equipment and materials are geared towards meeting the challenging requirements of the Oil and Gas industry and provide solutions for a wide range of applications. From recreating service parts to rapid prototyping of highly customized new components Xtmachining can help fuel your growth. Our focus on low-volume, highly customized parts aligns perfectly with the needs of the Oil and Gas industry. We have helped many customers re-manufacture old service parts that they no longer have CAD drawings for through scanning and reverse engineering. We can then produce limited quantities of the parts to keep important production equipment up and running and minimize expensive downtime.

Do you need it?

- Can you produce highly customized parts in small batches at a low price from a one-stop manufacturing partner?

- Rapidly manufacture legacy repair parts to keep critical production operations running?

- Rapid development cycle for complex prototype parts?

- Reduce production costs through part consolidation?

Ready to start your next project?

We provide high-performance plastic and metal material design and low-volume production solutions through basic manufacturing services such as injection molding and CNC machining. Contact us now.

Fabrication Services for the Oil and Gas Industry

We use state-of-the-art equipment to produce efficient, high-quality parts and assemblies and are fully capable of handling custom work as well as any standard-sized components required to complete your oil and pipeline projects. We offer a wide range of services to meet a variety of needs, including:

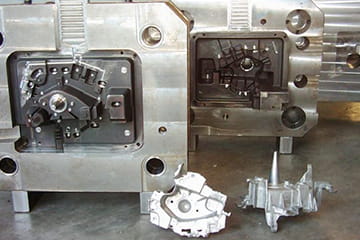

Plastic Injection Molding

CNC Machining

3D Printing

Rapid Prototyping

Sheet Metal Production

Die Casting

Components we manufacture for the oil and gas industry

- Hydraulic Fracturing Fluid Ends

- Directional Drilling Collars, Subs and Mandrels

- Artificial Lift Components Such as Pockets, Mandrels, and Bodies

- Sub-Sea Stack Components

- Large Shafts

- Blow Out Preventers (BOPs) Components, such as Ram Shafts, Locking Shafts, Bonnet’s

- Drill Rig Components, such as Top Drives, Links, Quills, Mandrels, Yokes, Pins, etc.

- Hangers

- Frac Valve Bodies, Powerframes and Flowline Components

- Connecting Rods

- Heavy Duty Stainless Steel Components

- Gearbox Components

- Actuators

Material Options

We frequently use the following materials when processing products for the oil and gas industry. Our technical material experts can provide customers with qualified material recommendations and confirm them through actual testing.

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- PVC

- Nylon

- Delrin

- PTFE

- UHMW

- Ultem

- PEEK

- Acetal

Post-treatment and surface finishing

We apply our expertise in surface finishing of oil and gas components to meet our customers’ requirements. Our work is always accurate and meets the industry’s stringent performance, safety and reliability standards. Below is a list of the surface finishing services we provide.

- Powder Coating

- Painting

- Polishing

- Passivation

- Water Transfer Printing

- Laser Carving

- Silk Screen

- CNC Machining

- Etching

- Brushed

- As-Machined Finish

- Multi-Color Anodized

- Hard Anodizing

- Sandblasting +

- Anodizing

- Iron black Anodizing

- Chrome Plating

- Blue Zinc Plated

- PVD

- Electrophoresis

- Nickel Plating

Value-Added Services

The oil and gas industry often operates in harsh offshore and onshore environments, from extreme temperatures to corrosive conditions. The chemicals used in this process can be corrosive, abrasive, and dangerous to touch. It is not easy to manufacture parts and components that can withstand these conditions. Any defects can lead to poor performance or complete failure, which can endanger the safety of people in this industry. However, you can rely on Xtmachining to provide the latest precision machining technology to withstand these conditions.

At Xtmachining, we produce quality machine parts for all your oil and gas industry needs. You can get machine parts made of any material in our in-house workshop. We provide complete project development, including value-added engineering, secondary services, assembly, project management, and quality services. We can handle medium to high volume production machining and assembly applications.

Put your parts into production today

Our team uses high-performance materials to design and manufacture solutions that can meet the needs of your specific application. Contact us today and we will help you get the job done!

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…