Aerospace

Xtmachining has a culture based on customer collaboration, working with customers to design and produce precision components that meet strict tolerances and quality standards, ensuring the structural integrity and reliability of the final product. No matter how complex the component, we have the most advanced machines to handle the task.

Providing Custom Machining Services for Aerospace Manufacturing

At Xtmachining, we rely on a team of engineers with many years of professional experience and professional manufacturing equipment to provide high-quality custom parts solutions for the aerospace industry.

We understand the need for perfection in design and manufacturing at different stages of the aerospace industry. There are high risks at every step of the project, so high-quality manufacturing partners and suppliers are needed from the beginning. This is why we will go the extra mile in manufacturing your parts, from material testing to assembly. Our engineers can work with you through CNC machining services, injection molding, sheet metal manufacturing and 3D printing services to accelerate your product development cycle, reduce risks and help verify designs through trial runs, hot fire tests and simulated releases.

Our advantages in aerospace parts manufacturing are that we have advanced equipment and a team of engineers with rich experience, which can manufacture custom parts with high precision, complex shapes, high strength and high temperature resistant materials; moreover, our quality management team will strictly control the quality of the whole process to ensure the reliability and consistency of each component; and we are also able to flexibly handle small and large batch production orders and respond quickly to customer needs.

Aerospace Product Development, Prototyping and Component Production

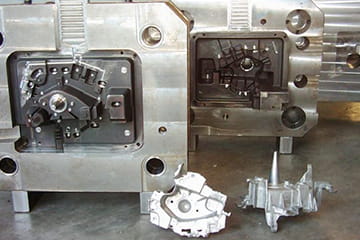

Xtmachining specializes in the manufacture of custom injection molded aerospace components as well as prototype parts and custom prototype tooling. Our company has unique facilities to accommodate aerospace product development, adoption of new design concepts, and design modifications to legacy parts for existing flight programs that require updated tooling. No matter what stage your project is at, we can provide a lean, streamlined solution for your contract manufacturing needs.

We also utilize 3D printing technology for rapid prototyping for product development and proof of concept. Whether it is Rapid Injection Molding (RIM), Additive Manufacturing, or CNC Machining services, our company’s extensive experience and flexibility in contract manufacturing allows it to serve consumer and commercial flight manufacturers as well as leading aerospace contractors nationwide.

Contact our aerospace experts today

As experts in custom precision components for a wide range of aerospace applications, the Xtmachining team can provide the highest level of quality and reliability for your aerospace projects. Contact us today.

Our Aerospace Custom Manufacturing Capabilities

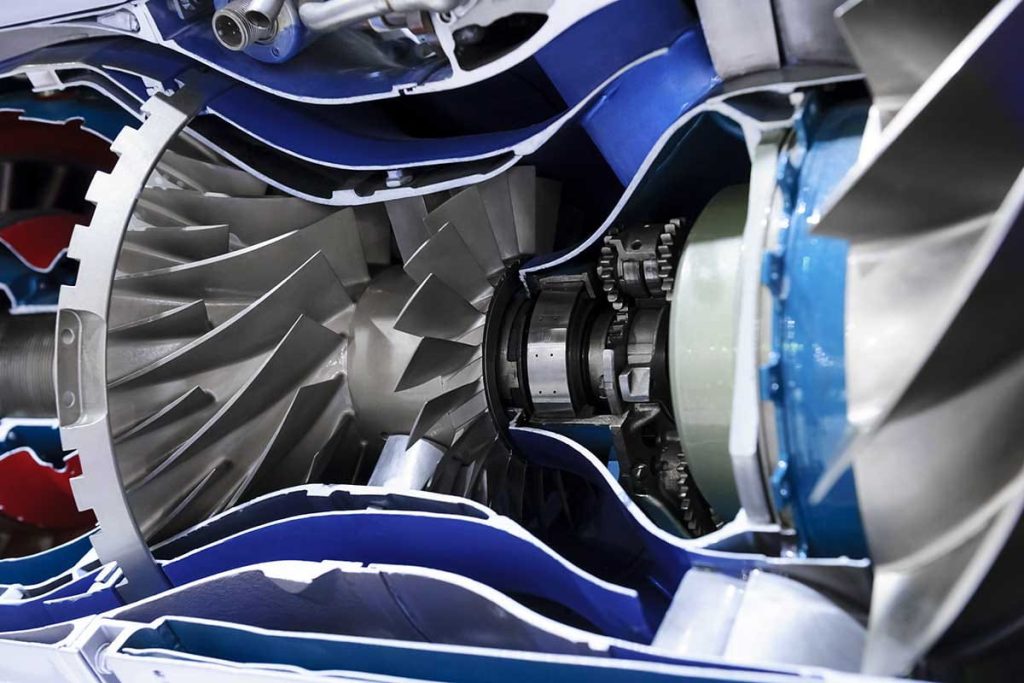

Providing a wide range of precision metal components designed specifically for aerospace applications plays a key role in advancing aviation technology. The components we supply are used in highly sensitive applications where failure is not an option, so we ensure that the components meet the highest standards of quality and precision.

Plastic Injection Molding

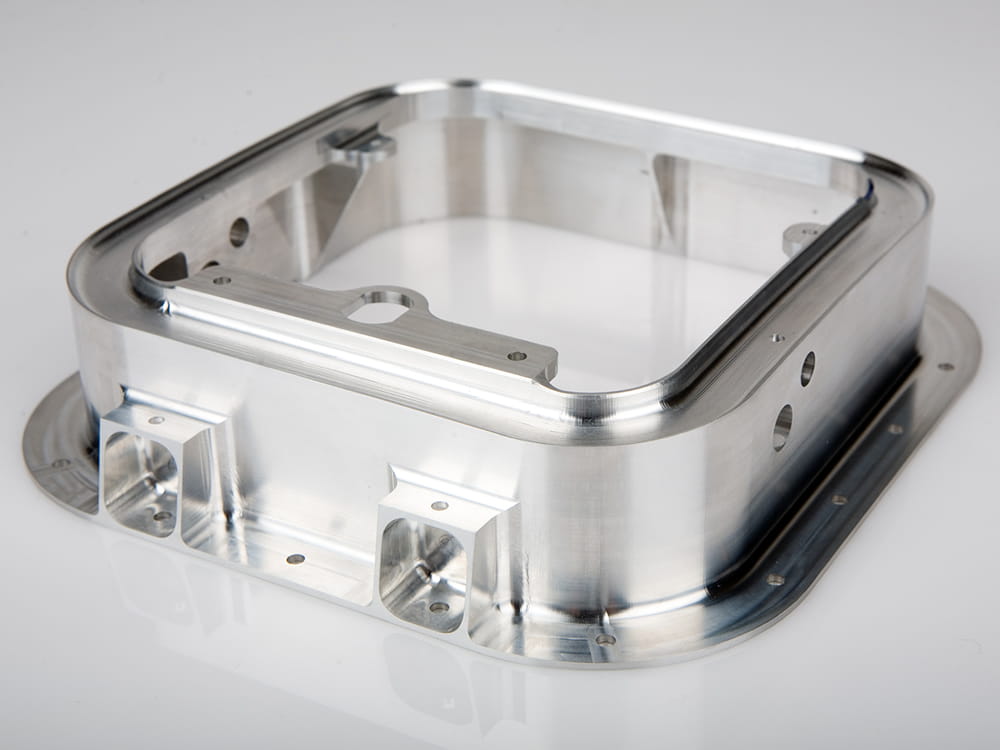

CNC Machining

3D Printing

Rapid Prototyping

Sheet Metal Production

Die Casting

How can we help you with your aerospace parts needs?

From the moment you contact us, you’ll speak with an engineer who will work closely with you to understand your needs. For example, we take a hands-on, personalized approach to DFM, ensuring that all potential issues are discovered and addressed early in the product development process. We’ll help you optimize part design, production processes, and material selection to get the best results at the best price. Our experienced engineers can help you move your project from prototype to production with confidence. And we’ll guide you to the best solution for the demanding environment your parts will be in. In short, we can help you accelerate your product development cycle.

High-quality aerospace component materials

Our material engineers follow the AS9100 (BS EN 9100) quality management standard commonly used in the aerospace industry, which covers injection molding and CNC machining using materials such as plastic composites, titanium, powdered metals, etc. Most of the plastic composites we use are PC, PA, PEEK, PEAK, LCP, PI, ABS, etc. Metal materials arealuminum, armor plate, brass, bronze, chromium, copper, gammalloy, Hastelloy, Incoloy, Inconel, Invar, manganese, Monel, nickel, Nitralloy, powdered metals, stainless steel, Stellite, titanium, Waspaloy, and many other superalloys, etc.

What kind of aerospace parts can we manufacture?

The aerospace industry requires products that meet precise specifications and the highest standards of reliability and quality. We can provide custom precision plastic and metal parts that meet and exceed these requirements as well as expert design. Combining technology with in-house engineering and manufacturing expertise enables us to design, manufacture and deliver the highest quality aerospace parts.

- Engine parts: turbine blades, turbine disks, combustion chambers and compressor components

- Structural parts: manufacture large-size, high-strength structural parts such as fuselage frames, wing spars, wing ribs, support beams

- Precision parts: manufacture precision mechanical parts such as navigation instrument housings, sensor housings and hydraulic valve bodies.

- Fasteners: provide high-strength bolts, nuts, rivets and other fasteners for aircraft and spacecraft assembly.

- Hydraulic and fuel system parts: processing of parts such as hydraulic pipe joints, fuel pump housings, nozzles, etc.

- Avionics parts: manufacture radar antennas, communication equipment housings and navigation equipment brackets.

Additive Manufacturing for Aerospace

Lead the future of aerospace with the shorter lead times, more affordable low-volume production, and unparalleled design freedom offered by Additive Manufacturing (AM). Through our certified flight component manufacturing, industry-leading software, and expert consulting services, we work with the entire aerospace supply chain, from OEMs to eVTOL startups, and from MRO to the supplier tier. Learn how we can support you at every stage of your journey.

Ready to start your project?

Talk to an aerospace parts customization expert today! Our team is standing by and ready to help you answer your questions or get a quote for your project.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…