Consumer Products

Xtmachining provides custom plastic parts for many different consumer products. With our product development knowledge and manufacturing experience, we are able to develop creative ideas into quality consumer products. We will help ensure your product is first to market at a fast pace.

Customized consumer product service provider

Xtmachining can help you create unique and tailored products to meet the needs of different categories of consumers. Our 3D printing, injection molding, CNC machining, sheet metal production and other services enable mass customization and personalization, helping companies diversify product lines and SKUs and meet seasonal demand and inventory management goals. We provide one-stop services from quality inspection at the raw material stage to ensuring that your final parts are produced quickly and economically according to specifications. Our technical team and manufacturing solutions help you produce parts quickly and economically and enter the market faster.

Consumer Product Components Contract Manufacturing

Our manufacturing services are carefully designed to meet the rigorous demands of the consumer product industry. We understand the rigors of the consumer product industry’s prototyping and tooling needs, and our quality control procedures and tools provide high-precision solutions. From consumer electronics to high-end kitchen and bath products, our contract manufacturing experts will help you move consumer product ideas from concept to prototype and mass-produced finished products faster and more efficiently to meet demanding project deadlines. Whether you are assembling fit and functionality test models, small batch production, or mass production parts, we can help you achieve your goals.

Ready to start your next project?

Upload your CAD design prototype and contact us. Our engineers will provide you with a free quote and design for manufacturability analysis, contact us today.

Consumer Product Manufacturing Services

As a consumer product manufacturer, Xtmachining can meet all of your production needs. We offer a full range of in-house capabilities. Partner with our consumer product contract manufacturing team to maximize your profitability, reduce costs, and get your product to market before your competitors with the perfect process.

Plastic Injection Molding

CNC Machining

3D Printing

Rapid Prototyping

Sheet Metal Production

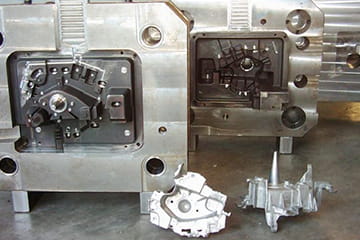

Die Casting

What Kind Of Consumer Electronics Parts Can We Make?

At Xtmachining, we provide our customers with a wide range of reliable parts required by the consumer industry and provide them with high-end standard manufacturing services. The following is a brief list of the products we can manufacture.

- Housing and Frames: Smartphone cases, tablet cases, laptop frames, TV cases, etc., provide protection and beauty.

- Structural Parts: Brackets, support frames, connectors, etc., ensure the stability and structural strength of the device.

- Internal Components: Circuit board brackets, heat sinks, interface panels, etc., support the installation and heat dissipation of electronic components.

- Buttons and Control Panels: Buttons, knobs, touch screen frames, control panels, etc., provide operation and control functions.

- Connectors and Joints: USB interfaces, audio interfaces, charging ports, etc., ensure reliable connection and signal transmission.

- Heat Dissipation Parts: Heat sinks, fan housings, heat pipes, etc., optimize the heat dissipation performance of the device.

- Decorations and Accessories: Decorative strips, logo panels, mirror decorative parts, etc., improve the appearance and user experience of the product.

- Protective Accessories: Anti-drop protective shells, screen protector brackets, etc., enhance the durability of the product and the user experience.

Common Materials

Your consumer product parts can be made from a variety of materials. We can provide DFAR, RoHS and REACH compliant materials upon request. Materials include, but are not limited to:

Metals

- Alloys

- Aluminum

- Brass

- Copper

- Stainless Steel

- Precision Steel

- Titanium

- Special Alloys

Plastics

- PVC

- Nylon

- Delrin

- PTFE

- UHMW

- Ultem

- PEEK

- Acetal

Post-Processing Services

We offer a variety of different surface treatments and coatings for plastic and metal prototype and production parts, depending on your application requirements. If a special process or coating surface treatment is required for prototype or production, please contact us.

Plastic Part Finishes

- Vacuum metalizing for metallic-like finishes, like chrome

- Plating for metallic finishes with nickel, chrome, copper, gold, and more

- Color-matched colorants, compounds, and materials

- Anti-static nickel coatings

- Soft-touch coatings to simulate over-mold grips

- Vapor polishing (or vapor smoothing)

- Dyeing

- Tumbling

- Bead blast

- 3D-printed textures

- Molded-in textures (urethane and injection molding)

- Painted finishes: textured, matte, gloss

- Part decorations (including labeling, silk screening, and pad printing)

Metal Part Finishes

- Heat treat

- Fluorescent penetrant inspection (FPI)

- Magnetic particle inspection (MPI)

- Passivation

- Plating for metallic finishes with nickel, chrome, copper, gold, and more

- match system

- Powder coating

- Anodizing

- Laser marking and engraving

Why choose Xtmachining for your consumer goods manufacturing project?

Xtmachining is an ideal choice for consumer goods manufacturers for many reasons. We provide high-quality manufacturing services tailored to our customers’ requirements. Our team uses the latest technology and equipment to produce innovative designs, prototypes and final products. The company has a team of experts in various fields who are available to support and guide customers throughout the manufacturing process. We provide a comprehensive service including design consultation, engineering and supply chain management to ensure that the final product meets the highest standards.

In addition, Xtmachining has a proven track record of delivering projects on time and within budget. We provide excellent customer service and are committed to meeting our customers’ needs and requirements. Xtmachining is a reliable and trusted partner for any consumer goods manufacturing project.

Get an accurate quote for your next project

Whether your project is complex or simple, metal or plastic, you will get an accurate quote within 6 hours.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…