Medical

Xtmachining can produce custom precision metal parts and plastic products with complex designs and tight tolerances for a variety of medical devices and instruments. Accelerate time to market and optimize your supply chain with rapid prototyping and on-demand production of medical components.

Professional Medical Parts Manufacturer

Do you need help turning medical product concepts into viable prototypes and production parts? Are you a medical device manufacturer looking for a manufacturing partner with extensive expertise in a variety of technical fields to help you bring medical products and ideas to market faster?

We are experts in understanding the unique needs of the medical field, whether it is new product prototype development management, mass production parts, or more specialized skills for special projects. Xtmachining is fully capable of using our expertise to help medical customers obtain high-quality products. The practices of the various industries we serve can benefit your medical projects and give you an edge over the competition.

Medical Device OEM Manufacturing

Xtmachining’s medical device contract manufacturing experience enables OEM manufacturing of the latest medical technologies and devices, and can provide turnkey solutions with long-term manufacturing programs. Our programmatic approach provides full control of prototype development, sourcing, product quality, kitting and assembly, inventory control, and on-time delivery of medical products from start to finish.

Our experience in medical device manufacturing solutions enables us to meet the rigorous and unique needs of the health and fitness industry. We pride ourselves on quality-driven, one-stop medical device innovation services with flexibility such as bridge tooling, low-volume production, rapid prototyping, and material diversity.

Contact our medical component experts today

The Xtmachining team is an expert in precision components for a wide range of medical applications, and can provide the highest quality and reliability for your next project. Contact us today.

Gain an advantage with expertise in medical component manufacturing

The rapid evolution of the medical industry requires continuous innovation and sophistication in medical device design. Smaller size, more complex geometries, advanced functionality and portability are the biggest demands on today’s medical devices and the biggest challenges facing design and engineering teams. Medical supplies, medical transport, surgical and diagnostic equipment, and other medical products are the backbone of quality healthcare. However, details can be the difference between life and death in medical manufacturing. We share your attention to detail, providing superior validation, quality control, and complete manufacturing solutions that exceed your most complex requirements.

Many of our customers in the medical industry have unique validation, quality, and certification requirements to maintain their competitive advantage in the market. Our account team, engineers, and quality experts have decades of experience navigating these situations to deliver exceptional outcomes for our medical customers.

We invest in the engineering talent, quality management, and technology needed to produce high-tolerance, precision parts to meet the needs of every product or solution we manufacture. These investments result in rapid scalability for our customers without sacrificing quality or validation.

One-stop medical device custom manufacturing services

We provide precision manufacturing for medical devices and parts primarily through rapid prototyping and low-volume production services. Through creative and agile manufacturing technologies such as 3D printing, injection molding, sheet metal production, polyurethane casting, and precision CNC machining, customers take advantage of our manufacturing range, no minimum order requirements, faster delivery times, and mass customization to get to market faster.

Plastic Injection Molding

CNC Machining

3D Printing

Rapid Prototyping

Sheet Metal Production

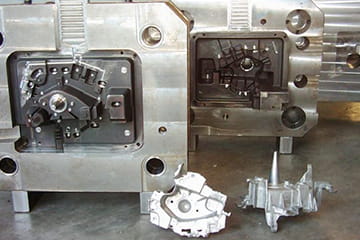

Die Casting

What Kind Of Medical Parts Can We Make?

Our proven ability to deliver custom, high-precision components tailored to the unique needs of the medical device industry sets us apart. Our team of engineers, manufacturers, and quality assurance experts combine experience, expertise, and experimentation to produce a wide range of durable, reliable, and accurate precision metal products. We ensure that all components meet stringent medical device quality control and compliance standards.

- Surgical Instruments: Processing of high-precision surgical instruments such as scalpels, scissors, forceps and tweezers, ensuring their sharpness and durability.

- Implants: Manufacturing of hip, knee, spinal and dental implants, ensuring their biocompatibility and mechanical properties.

- Diagnostic Equipment Parts: Manufacturing of precision parts such as ultrasound probes, CT scanner components, MRI equipment components, ensuring their high accuracy and reliability.

- Microfluidic Devices: Processing of microfluidic chips and devices for laboratory testing and diagnosis, ensuring their complex microstructure and functionality.

- Pumps and Valves: Manufacturing of medical infusion pumps, syringe pumps and various medical valves, ensuring their precise control and durability.

- Housings and Brackets: Processing of housings and brackets for medical equipment, such as monitor housings and instrument brackets, ensuring their sturdiness and durability.

Material Options

With unparalleled experience working with a wide range of materials, including specialty alloys and materials with the specific properties required for medical applications, we deliver durable and reliable components that can perform in the most challenging environments.

Metals

- Stainless Steel

- Inconel

- Kovar

- Titanium

- Titanium-Zinc

- Aluminum

- Copper

- Nickel

- Niobium

- Molybdenum

- Brass

- Cold Rolled Steel

- Beryllium Copper

- Nickel Silver

plastics

- ABS

- Polycarbonate

- Polypropylene

- Polystyrene

- LDPE

- PVC

- Acrylic

- Resin

- Nylon

- Glass-filled nylon

- POM

- Fiber-reinforced plastic

- PET

- PEEK

- Propylene

- Polyethylene

Surface Treatment

According to customer requirements, we provide customers with a variety of surface treatments for different effects and materials. In addition to the above conventional surface treatments, there are also a variety of special surface treatments. If special processes are required, please indicate when contacting us.

- Powder Coating

- Painting

- Polishing

- Passivation

- Water Transfer Printing

- Laser Carving

- Silk Screen

- CNC Machining

- Etching

- Brushed

- As-Machined Finish

- Multi-Color Anodized

- Hard Anodizing

- Sandblasting +

- Anodizing

- Iron black Anodizing

- Chrome Plating

- Blue Zinc Plated

- PVD

- Electrophoresis

- Nickel Plating

Cleanroom Injection Molding Production Environment

Medical and laboratory technology plastic molded parts require strict hygiene standards and advanced injection molding production technology. The injection molds used in our production use the highest quality raw materials and mold components. Most medical products require cleanroom injection molding.

I understand the special requirements for the maintenance, inspection, cleaning and storage of injection molds for medical device parts. The mold steel used in medical device production must be rust-proof stainless steel. The risk assessment, validation, quality control and product production of medical and laboratory technology injection molds make them more expensive than standard plastic molds.

Xtmachining has a 100,000-level (ISO8-level) dust-free injection molding workshop, which is well suited to assist medical manufacturers in production. We support the injection molding production of plastic molded medical products in a cleanroom environment and are committed to meeting the highest industry standards.

Get an accurate quote for your next project

Whether your project is complex or simple, metal or plastic, you will get an accurate quote within 6 hours.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…