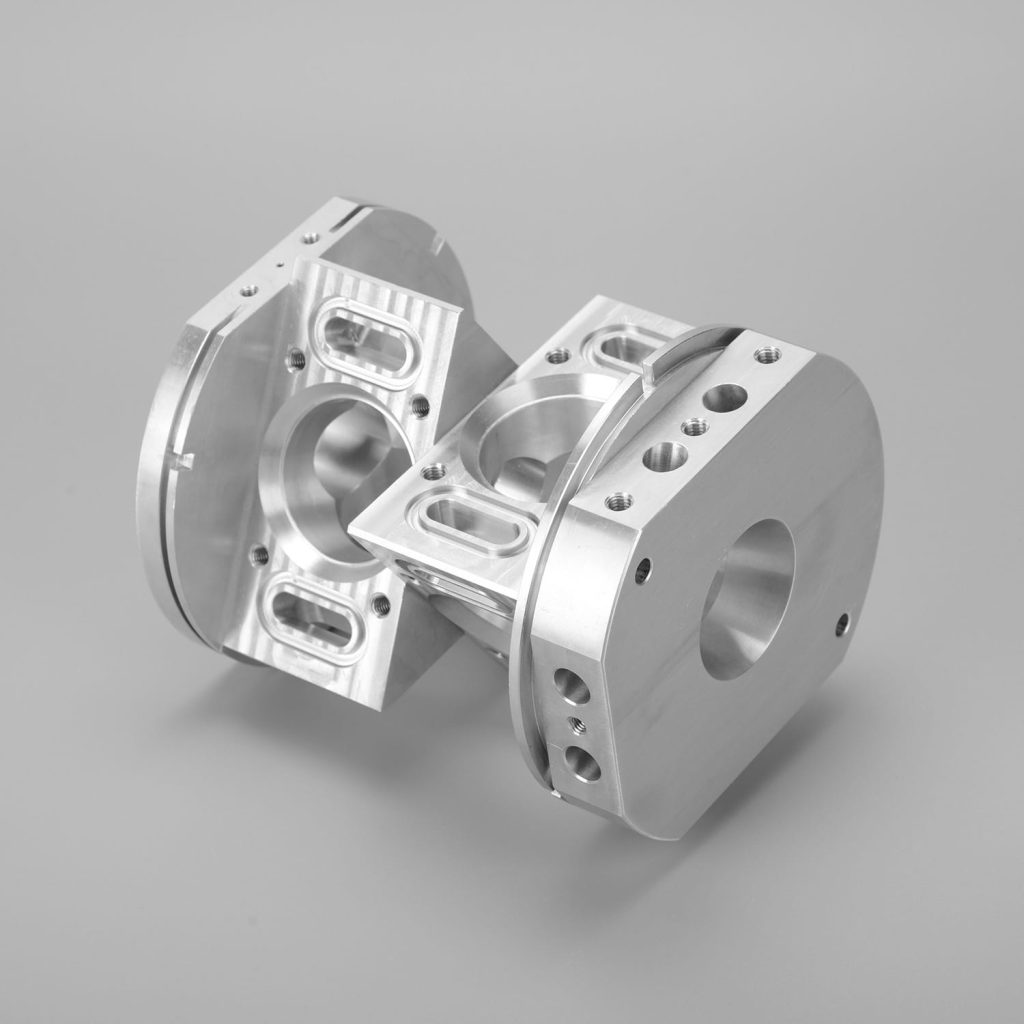

5 Axis CNC Machining Services

5-axis CNC machining solutions designed to grow your business. Get high-precision, accurate, complex machined parts with extremely complex geometries. Get instant CNC online quotes.

Custom Precision 5-Axis Machining Supplier

Xtmachining is unique in that we have a team of highly skilled engineers and machinists who work closely with our customers to understand their unique needs and provide custom solutions to meet those requirements. We deliver custom parts with high precision, regardless of part complexity. Our team of certified machinists combines decades of shared experience with the latest manufacturing technology to ensure unmatched quality at a competitive price. And we are committed to maintaining the highest quality standards, using a rigorous quality control process. Every part we produce is thoroughly inspected to ensure it meets the stringent precision and quality standards that the company is known for.

In addition to our machining expertise, we also provide value-added services to facilitate the delivery of finished components. Our other in-house capabilities include welding, coordinate measuring machine (CMM) inspection and light assembly, sealing services, and temporary solutions for critical components for your production line.

Our 5-Axis CNC Machining Capabilities

5-axis CNC machining enables us to machine high-quality, high-precision parts in virtually any shape and other parts and components that are difficult or impossible to produce accurately in other ways. We are able to machine to tolerances of ±0.0005 inches or better, with positioning accuracy of 0.005 microns and angular accuracy of 1°. As a result, there is essentially no limit to the products we can produce. Whether you need a prototype, a one-off product, or a full-scale production run in quantities of thousands, our 5-axis machining services can provide you with dimensionally perfect parts from the first piece to the last.

Efficient In-House Management

We also have an efficient, advanced supply inventory management system, so you never have to worry about reordering or running out at the wrong time! We can accommodate any delivery frequency, whether it be daily, weekly or monthly. The flexibility of our manufacturing allows us to adjust shipping quantities and frequencies as needed to meet changes in product demand.

We document each job by saving procedures, setup sheets and digital pictures of the setup. This information includes any deburring and finishing instructions. This information is integrated with our ERP software so all manufacturing information is associated with the job and backed up on our network. This documentation allows us to quickly setup your job in the future and helps ensure consistent part quality from one run to the next.

Ready to start your next project

Ready to experience the precision and quality of Xtmachining’s 5-axis CNC machining services? Contact us today to discuss your project requirements or request a quote. Choose Xtmachining for your needs and experience the difference in quality and service.

Five-axis machining types

Xtmachining has a variety of five-axis machining capabilities, we are able to produce high-precision and high-quality parts to meet your special requirements. You are guaranteed to get safe products from prototype design to mass production, and you don’t have to worry about tolerances, appearance or any other defects.

3+2 axis CNC machining

4+1 axis CNC machining

Full 5-Axis CNC Machining

Quality Management

- Strict quality control process: IQC (Incoming Quality Control), FAI (First Article Inspection), IPQC (Input Process Quality Control), OQC (Outgoing Quality Control) and COC (Certificate of Conformity) can be provided according to your requirements.

- A wide range of testing methods and testing tools, such as pin gauges, colorimeter, etc.

- Various testing equipment: CMM, flash measuring machine, 3D scanner, 2D image measuring machine, etc.

- Highly skilled QA team with more than 10 years of experience.

- Strict quality control system to maintain process improvement and optimization.

- Material certificates and test reports can be provided upon request.

5-Axis CNC Machining Available Materials

We carefully select the materials from which we machine our parts based on your project needs. Our engineers are skilled in producing high-tolerance surfaces at low cost using a variety of metals and plastics, such as:

CNC Metal & Alloy Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

CNC Plastic Materials

- ABS

- PA(Nylon)

- PC

- PE

- PET

- PMMA(Acrylic)

- POM (Acetal)

- PP

- PTFE

- PEEK

- And more

Composite Materials

- Glass & Fibers

- Perspex

- Styrodur Glass

- Glass fiberboard

- Aramid fiberboard

- Carbon fiberboard

5-axis CNC machining surface finish

Xtmachining offers a wide range of surface treatments to improve the surface quality of your 5-axis machined parts. Surface treatments can help improve component appearance, performance, surface finish, hardness, corrosion resistance, and hide visible tool marks on the product surface.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Polishing (Ra 0.8μm / Ra 32μin or better)

- Bead Blasting

- Tumbled

- Bead blasted

- Anodized type

- Black Oxide

- Powder Coated

- Chromate Conversion Coating

- Plating

- DLC (Diamond-Like Carbon) Coating

Contact Us for Full-Service 5-Axis CNC Machining Services

If you are looking for precise, efficient and customized solutions for your machining needs, look no further than Xtmachining. Contact us today to experience our exceptional service and commitment to excellence.

What is 5-axis machining?

As a subtractive machining process, a 5-axis CNC machine is a tool that is capable of manipulating a workpiece along multiple axes. These machines remove excess material from the workpiece during the milling process. In addition to the regular 3 axes (x, y, z), 5-axis machines can also move the base along additional fourth and fifth axes by rotating the spindle. Like most multi-axis CNC and milling machines, 5-axis machines are defined by 3 main components.

Like other CNC machining equipment, 5-axis CNC machines also rely on 3D CAD design, CAM programming instructions, and experienced operators to oversee the entire process. After the part design is created, the next step is G-code, which controls the linear movement of the cutting tool and the movement of the table along the rotational axis. The provision of tools, lubrication, and other important matters are all arranged. When the process is over, we will have a beautifully made part.

Benefits of 5-axis CNC machining

- High precision: 5-axis CNC machining can handle complex designs with tolerances up to ±0.005mm, ensuring high-quality results for your complex projects.

- Flexibility: 5-axis CNC machining is able to manufacture parts with unique shapes that cannot be made by other methods. This can provide more design and functional options.

- Time savings: 5-axis CNC machining can set up the process once, meaning parts can be machined faster and with fewer potential errors. Production schedules can be shortened and time to market can be reduced.

- Fast production: Extremely short delivery times allow for quick response to market demands and maintain a competitive advantage. And whether it’s meeting tight schedules or quickly scaling up production, 5-axis CNC machining can do the job.

- Cost savings: Despite the higher initial cost, the long-term benefits of 5-axis CNC machining can result in significant cost savings. Fewer setups, less waste, and faster delivery all contribute to a more economical production process.

5-axis machining vs. 3D printing

5-axis machining is the process of machining precision parts by removing excess material. During 5-axis machining, the workpiece is often significantly altered. 5-axis CNC machining can instruct cutting tools to create grooves and drill holes to produce a finished part from a workpiece.

In contrast, the 3D printing process is completely different, with software programs directing the use of a powdered substrate and a dedicated computer printer to automatically build the desired shape. Today, 3D printers can create parts from both plastic and metal materials. But because 3D printing can take a lot of time to complete, in most cases this manufacturing process is not commercially comparable to machining.

Industries We Serve

5-axis CNC machining is used to produce parts used in many different industries due to its efficiency and ability to produce complex shapes. This process is increasingly valuable across multiple industries. Here are some examples of industries that most commonly utilize this technology:

Start your 5-axis CNC machining project today

Are you having trouble getting quality parts, on-time delivery, or reliable service? Get a free quote and experience the Xtmachining difference.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…