CNC Machining Services

Our in-house capacity can deliver your CNC machined parts to design specifications, on time, at affordable factory prices. And, our facility is designed for rapid prototyping and low-volume production of end-use components.

One-Stop Custom Machine Parts

Whether innovating or producing, you need a machining partner that’s always fast and high quality. Long lead times can cost you valuable time by impacting productivity and complicating scheduling. Our unique custom manufacturing process offers 2-3 day lead times with no minimum order requirements. And get your machined parts fast, with the consistent quality you need, backed by a true team dedicated to your success.

Because we understand that long lead times and inconsistent quality can interrupt your flow. When you have to wait weeks to get a part, or go through rework cycles, you miss important project timelines, which can drag down your entire organization.

Why Use Xtmachining’s Machine Shop

When considering which machine shop to work with, the first thing to consider is capability. Does the supplier have the right equipment? Do they have a proven track record? Can they deliver parts to us on time? Xtmachining does all of that, and we do it better!

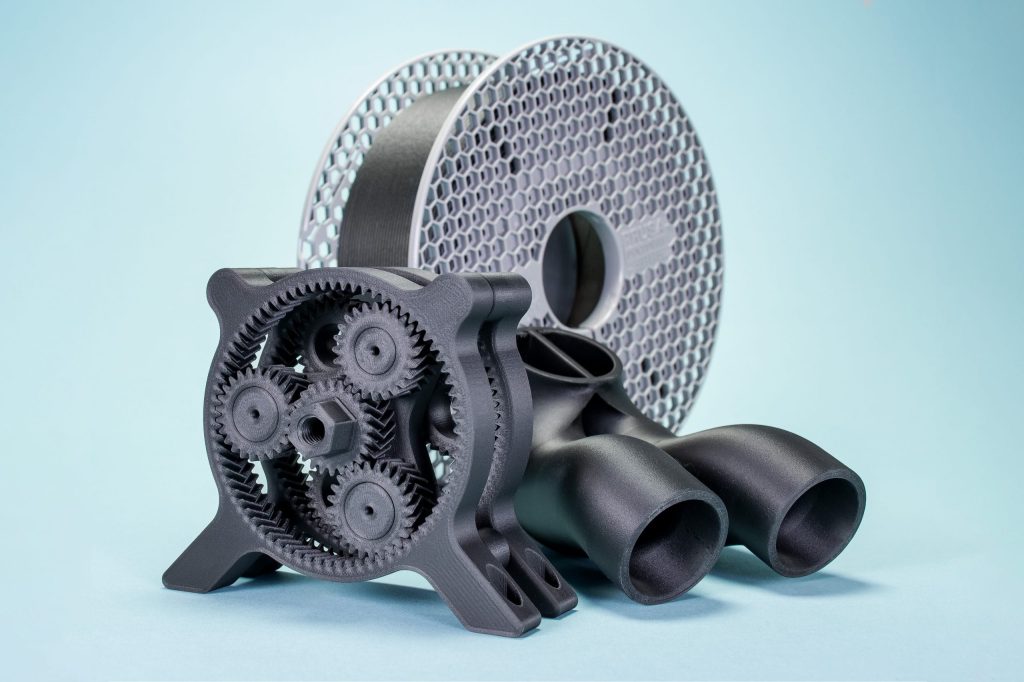

We can provide unique and innovative solutions for each of our customers. Our team of engineers can develop adaptive tooling and fixtures in-house to ensure safety and quality. Plus, in-house 3D printing gives us greater flexibility and the option to test multiple methods to create an efficient and robust process.

Our Comprehensive CNC Machining Capabilities

We want to provide you with the best custom machining and the best service. We are committed to achieving the highest levels of machining accuracy and adhering to the most stringent standards. We are also committed to meeting your needs because we are a service business.

Our capabilities include laser-detected centerless grinding, CNC milling, wire EDM, sinker and keyhole EDM, turning, surface and profile grinding, and more, with tolerances of ±0.0002 inches. You may not always need this level of precision, but it demonstrates the reliability you can expect from Xtmachining. We not only adhere to your specifications, but we are fully responsive to your needs. From a single prototype to the highest volume component production runs, every shipment is provided with full documentation and certification.

We're ready to develop your solution

Tell us more about your custom part or product and your industry in our quick and easy quote request form. Or give us a call to speak with one of our engineers.

Types of Our CNC Machining Services

Xtmachining provides custom CNC machining solutions for engineers, product developers and designers looking for prototyping and low-volume production. Whether it is a simple or complex design with tight tolerances, our CNC machining shop guarantees excellent quality.

5-axis machining

CNC milling

CNC turning

Rapid Prototyping

Metal Part Forging

Finishing Services

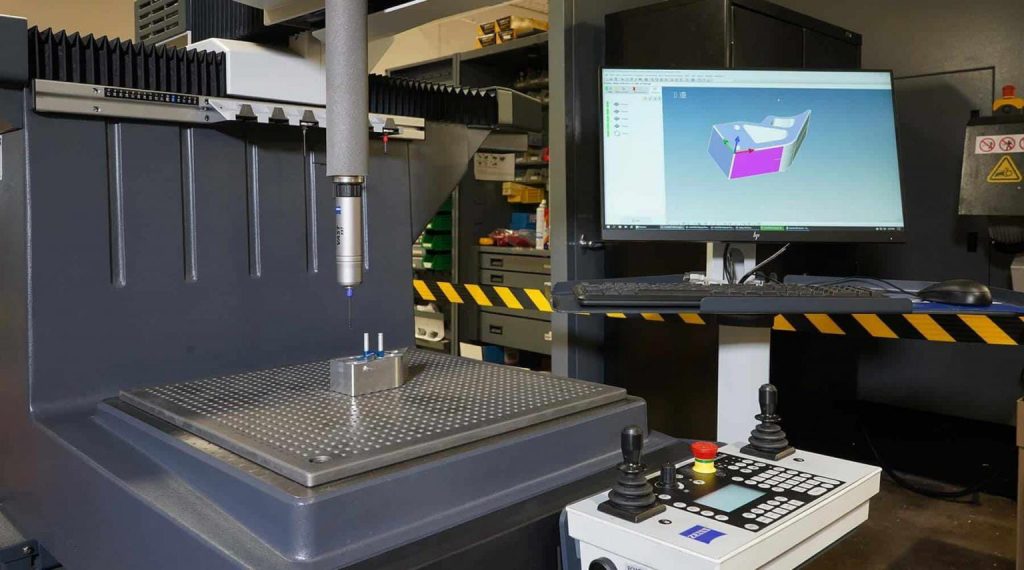

Quality Control Equipment

- Digimar CX1 Digital Height Stand

- Brown & Sharp Optical Comparator

- Omano Digital Microscope

- Helmel Checkmaster 216-142 Manual CMM (Coordinate Measuring Machine) for 3D Measurement

- Mitutoyo SJ410 & Mitutoyo SJ-210 Profilometer

- Vermont Gage Pin Gages

- Starrett and Mitutoyo Calipers, Micrometers

- OGP Smartscope Flash 500, Zone3 Software Package for 3D Model based measurement, 500MMx450MMx300MM measurement range, Touch Probe, TTL (Through the Lens) Laser

- Clark CRM-12 Hardness Tester

Our Team of Engineers Capabilities

At Xtmachining, we go beyond just manufacturing parts, we offer custom CNC machining services. We understand the importance of having the perfect part. So, whether it’s a small CNC machined part or a large component, send us your blueprint and our team of engineers will custom machine it to your exact specifications in whatever material you require. Don’t have a blueprint, but just an idea of what you need? No problem. Our team of experts can take your idea, work with you to make improvements (if needed), and turn it into a working part or prototype. All work comes with a quick turnaround and at a fraction of the cost.

No matter what industry you’re in, it’s critical to deliver products to your customers quickly. As the market continues to change, manufacturers who can’t keep up will be left behind. Get the precision parts you need, when and where you need them, with the support of Xtmachining. We are a full-service machine shop capable of producing parts with complex geometries and tight tolerances.

We are the contract machine shop that grows with you

Providing scalable contract manufacturing for your critical components. Dependable results driven by highly qualified people and processes.

Driven to Deliver

Our team’s winning spirit, from the owners to the manufacturing floor, drives us to deliver for our customers.

Constant Updates

A dedicated project manager meets with you weekly with the details, even the occasional bad news.

Detailed Planning

Our planning covers it all including materials, outside operations, and tooling so you don’t.

CNC Material Selection

Our CNC machining services are compatible with a wide range of materials, including many metals, plastics, and composites. If you don’t see the material you need, our team is happy to machine a product from a customer-supplied material or source it ourselves. Having us source your metal or plastic raw material saves you energy and time, allowing you to focus on what you do best.

CNC Metal & Alloy Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

CNC Plastic Materials

- ABS

- PA(Nylon)

- PC

- PE

- PET

- PMMA(Acrylic)

- POM (Acetal)

- PP

- PTFE

- PEEK

- And more

Composite Materials

- Glass & Fibers

- Perspex

- Styrodur Glass

- Glass fiberboard

- Aramid fiberboard

- Carbon fiberboard

Surface Finishing Options

We also offer a complete range of surface finish options for our precision machined components. If you require a custom surface finish outside of this list please contact us as we can most likely provide it for you.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Polishing (Ra 0.8μm / Ra 32μin or better)

- Bead Blasting

- Tumbled

- Bead blasted

- Anodized type

- Black Oxide

- Powder Coated

- Chromate Conversion Coating

- Plating

- DLC (Diamond-Like Carbon) Coating

Request a Quote for Your Next Project

Do you need a quote for high precision parts? Contact us today by phone, email or using our contact form.

What is CNC machining?

CNC machining, also known as computer numerical control machining, is a manufacturing process that primarily involves the use of computer-controlled machine tools to produce precise and complex parts from a variety of materials. The process involves using a computer program to control the movement and operation of the machine tool, allowing for a high level of accuracy and repeatability.

In CNC machining, the machine tool can be a milling machine, lathe, drill press, or other type of machinery that can be controlled by a computer program. The program provides instructions to the machine tool on how to move, rotate, and position the cutting tool in order to shape the workpiece into the desired shape and size. CNC machine tools are capable of producing complex shapes that would be difficult or impossible to achieve using manual machining techniques.

What are the benefits of custom CNC precision machining?

CNC machining services provide state-of-the-art ultra-sharp, clean cuts to produce parts with extremely close tolerances. High-precision CNC machining is suitable for one-off jobs and small to large batch production due to its high repeatability. Key benefits when using CNC machines to manufacture parts include:

- Accuracy

- High repeatability

- Achieve very tight tolerances

- Material has excellent and fully isotropic physical properties

- Suitable for most engineering applications

- Cost-effective for complex geometries

- Excellent speed to market

Trusted from Prototype to Production

High-quality service is all about giving our customers the best possible experience. Whether it’s through attentive customer service, fast delivery of goods, or providing services that exceed expectations and solve customer problems, high-quality service is the key to ensuring customer satisfaction. We know how to manufacture some of the most critical, high-precision parts in the world. Our commitment to ISO 9001:2015 quality standards drives every project. From small, intricate cuts to large projects, we complete all jobs with ease and efficiency.

CNC Machining vs. 3D Printing

When custom machined metal parts are needed, machining is always a better choice than metal 3D printing. CNC machining offers a wider range of materials, better surface finishes, and is typically less than a quarter the price of metal 3D printing. CNC machining is also a great solution for complex tools such as injection molds.

CNC machining plastics is slightly more complex, and machining plastics is generally more expensive, requires longer lead times, and has more design restrictions than 3D printing, especially when compared to HP Multi Jet Fusion. However, CNC machining works with more plastics than 3D printing. If the material you need cannot be printed, CNC machining is a good option.

Industries We Serve

We process products according to your drawings or specifications. If you have an idea but not a fully realized design, our experts can help you go from concept to finished product in no time. The industries we serve include:

Get a quote for your next project now

What can we do for you today to ensure you receive the best quality service? Our experienced team of professionals is here to answer any questions you may have and customize a solution to meet your unique needs. We pride ourselves on providing impeccable customer service and attention to detail, so you enjoy a worry-free experience from start to finish.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…