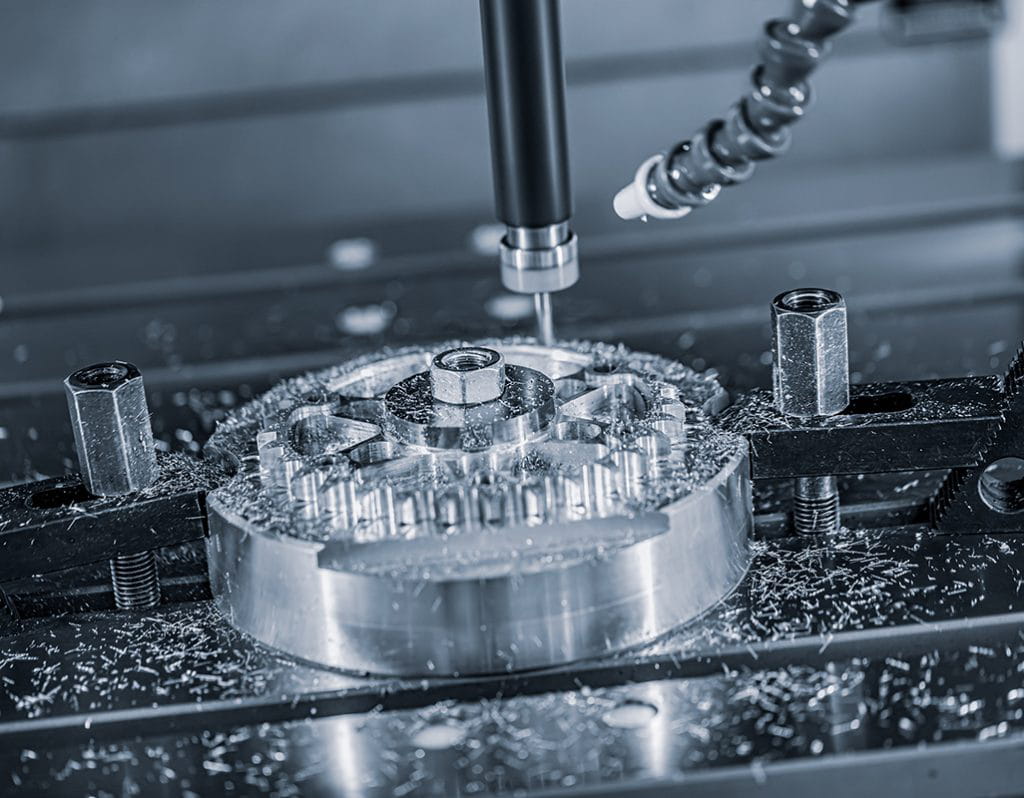

CNC Milling Service

Get instant quotes for custom metal and plastic CNC milled parts for prototypes, low-volume and high-volume production at the lowest cost.

Precision CNC Milling Shop to Build Your Parts

As a leading CNC milling service provider, Xtmachining has the team and expertise to deliver exceptional results. We are well-equipped to handle a wide range of projects using advanced equipment and technology. We focus on precision and efficiency to ensure that each CNC milling project meets the highest quality standards.

Work with us and let us turn your product design or idea into reality with our first-class CNC milling services. We can provide CNC milling services for almost any design and a variety of metals and plastics. Our team of highly qualified engineers and machinists use state-of-the-art multi-axis milling machines to complete your product in one go. We also have a dedicated quality control team that tests and ensures that all CNC machined parts meet customer requirements as well as required standards and regulations. In addition to this, our many other manufacturing and finishing capabilities provide a comprehensive and satisfactory solution for your product development project. And all services have no minimum order quantity (MOQ), making it easy for you to find the perfect solution to meet your needs.

Our Capabilities

We offer 3, 4 and 5-axis CNC milling, horizontal machining, CNC turning, grinding, part assembly, part marking and engraving, and quality inspection services to meet our customers’ stringent quality and delivery requirements. Xtmachining can produce the most complex parts with inter-feature and profile tolerances of ±0.0005 inches and positional tolerances of ±0.001 inches or better.

From our independent, environmentally controlled quality lab, to our technologically advanced CNC equipment and skilled machinists, we are well suited and 100% committed to providing the repeatable quality components you need within rapid prototyping and development timeframes.

CNC Milling General Tolerances

We offer a wide range of CNC machining tolerances to meet your specific design needs, including GD&T callouts. Depending on your part geometry and selected material, we offer standard and custom thread sizes with tolerances up to ±0.001 inches. Our default CNC milling tolerances for metals follow ISO 2768-m, while for plastics we follow ISO 2768-c.

We can solve your problems and meet your needs

We ensure consistent part quality by providing quality products, timely delivery at the best value and competitive pricing to meet customer and regulatory requirements, and continually improve our management system.

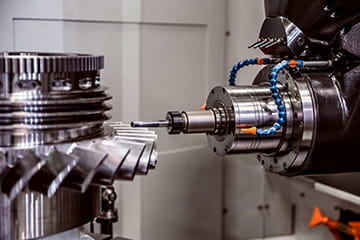

CNC Milling Production Capabilities

Our CNC milling production capabilities are very strong, and we have a range of advanced milling machines equipped with multi-axis capabilities, allowing us to accurately process complex geometries. Our skilled operators and cutting-edge technology ensure high-quality components, fast turnaround times, and the ability to meet a variety of manufacturing needs.

Metal CNC Milling

Plastic CNC Milling

Wood CNC Milling

Material Options

Xtmachining offers a wide variety of materials for custom CNC machining, plastics, and metals. If your project requires a material that is not on the list, please let us know! We can accommodate other material requests, but may require more time to quote while we source the material.

Metal & Alloy Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

Plastic Materials

- Alloy Steel

- Mild Steel/ Low CarbonSteel

- Tool Steel

- Stainless steel

- Copper

- Brass

- Aluminum Alloys

- Titanium

- And more

Surface Finishes

We offer a wide variety of high-quality surface finishes, each with unique properties to meet your specific application needs.

- As machined (Ra 3.2μm / Ra 126μin)

- Smooth machining (Ra 1.6μm / Ra 63μin)

- Polishing (Ra 0.8μm / Ra 32μin or better)

- Bead Blasting

- Tumbled

- Bead blasted

- Anodized type

- Black Oxide

- Powder Coated

- Chromate Conversion Coating

- Plating

- DLC (Diamond-Like Carbon) Coating

Design considerations

- Corner radii should preferably be 10% or more of the wall height.

- Avoid fragile shapes.

- Provide shapes that are easy to hold during machining, such as straight edges.

- Fragile shapes are difficult to machine, such as elongated shapes and thin walls, because the milling process puts pressure on the material.

- Produce cut surfaces with visible patterns due to the rotation and movement of the cutter.

- We stock a wide range of materials, use state-of-the-art machines, and strictly follow all design specifications.

Types of CNC Milling Machines

We have a wide range of CNC milling machines to suit your parts production needs. We can meet your unique custom part requirements.

Vertical Milling

Horizontal Milling

3-Axis CNC Milling

4-Axis CNC Milling

5-Axis CNC Milling

9-axis mill-turn

Looking for a reliable CNC milling parts supplier?

Speak with a member of our team today, get a free quote, or get additional information about any of the services we offer.

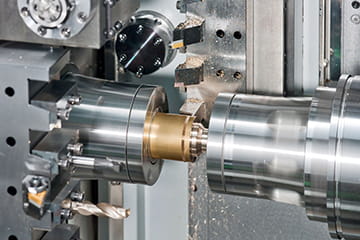

How CNC Milling Works

The CNC milling process begins with designing a 2D or 3D CAD part. The finished design is then exported to a CNC-compatible file format and converted via CAM software into a CNC machine program that instructs the machine on the workpiece and tool movements. Before running a CNC program, the operator must prepare the CNC milling machine by attaching the workpiece to the machine’s work surface (table) or workholding device (such as a vise) and attaching the milling cutter to the machine’s spindle. Depending on the specifications and requirements of the milling application, the CNC milling process employs either a horizontal or vertical CNC milling machine, and rotating multi-point (multi-tooth) cutting tools such as milling cutters and drills. When the machine is ready, the operator initiates the program via the machine interface, instructing the machine to perform the milling operations.

Benefits of CNC Milling

CNC milling is ideal for creating angled shapes, channels, slots, holes, curves, chamfers, and other complex geometries and smooth surfaces. Milling offers several advantages over other manufacturing processes. Milling is cost-effective for small batches. It also reduces lead times because parts can be made in minutes, whereas traditional machining processes such as injection molding can take days (sometimes weeks) to complete.

Industries We Serve

CNC milling services are used in a wide range of industries and play a key role in the production of important components. Below are some of the industries we serve.

Get started on your next CNC milling project

Please tell us about your project including material, color, quantity and finish. Please provide as much information as possible so we can provide you with an accurate quote.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…