Injection Molding Services

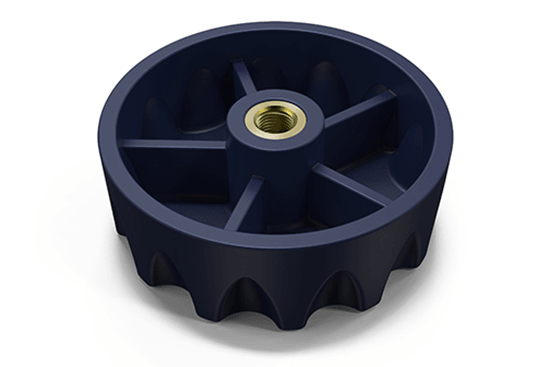

Whether it is a small component or a large component, Xtmachining can produce the products you need. We can design and customize plastic parts and assemblies to enhance the end product, reduce overall part and production costs, and simplify the assembly and manufacturing process.

Transforming Your Designs into Mass Production

Xtmachining’s Plastic Injection Molding division was founded on the principles of innovation and being a world-class manufacturer. We combine strong in-house tooling, highly engineered solutions, automation, and complete plastic injection molding capabilities. We provide high-quality, high-precision injection molded parts to customers across a wide range of industries. We specialize in designing and manufacturing rugged injection molds to produce custom parts to our customers’ exact specifications. State-of-the-art automated production equipment and highly skilled staff enable us to provide precision molded parts to meet the most demanding design requirements.

We offer dedicated cleanrooms for medical and other applications with stringent cleanliness requirements. We offer a variety of critical tooling applications, and we are certified for quality control. A range of ancillary services are also available to save you time and money and help you get your products to market on time.

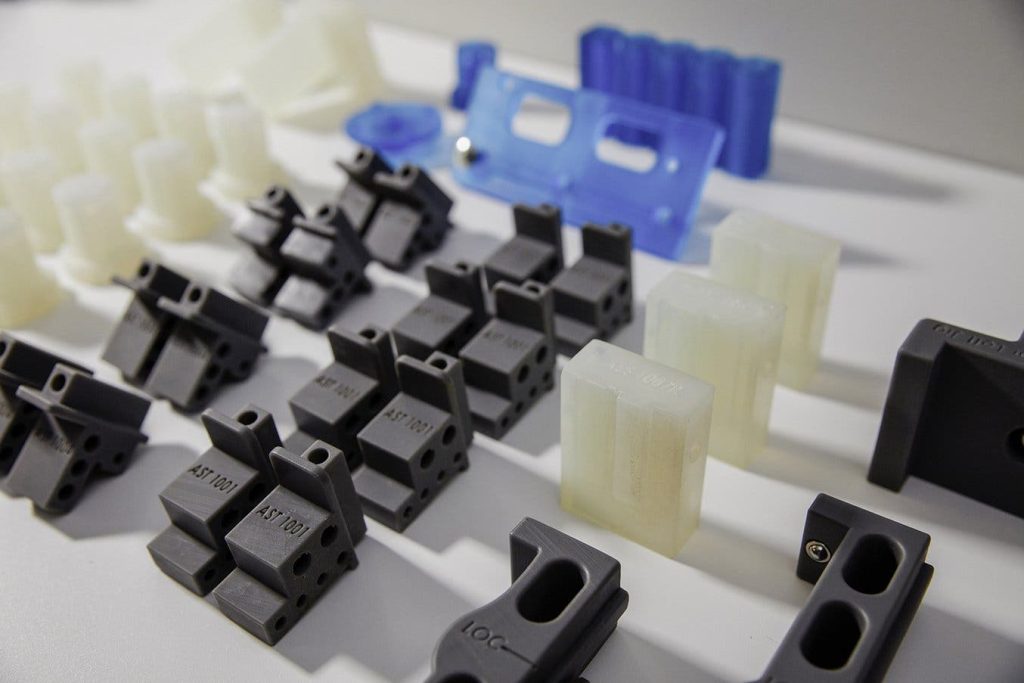

We specialize in new product development, from prototype parts to complete small batches to high-volume production. We will work with your engineering team to improve your design to make it better fit, better look, more functional, and easier and more efficient to manufacture. From unique custom molds to complex geometries to parts with extremely close tolerances, Xtmachining can do what other plastic injection molding companies can’t.

A better choice for your fast, low-volume production needs

We have the experience and equipment to deliver unmatched speed, flexibility, and support. We leverage our exceptional molding expertise to provide comprehensive technical guidance and tooling options for your project. We continually improve our production processes, implementing new methods to reduce inefficiencies and shorten lead times for our customers. Whether you are looking for short-run production, rapid tooling, or prototyping services, we can help you find the best solution and deliver it quickly and efficiently.

Low-volume molding projects typically require less than 10,000 pieces per year, and Xtmachining has 100-ton, 165-ton, and 2000-ton plastic injection molding machines in-house with the ability to scale up production as needed. Our ideal customers for low-volume molding place a high value on supplier relationships, where we focus on problem-solving, proposing solutions, and sharing aspects of tool design and optimized processing.

Custom Plastic Injection Molding Service Types

We can handle everything from plastic prototypes to production parts with a standard lead time of 15 business days. For projects that require a quicker turnaround, our quick turnaround injection mold service is the perfect solution.

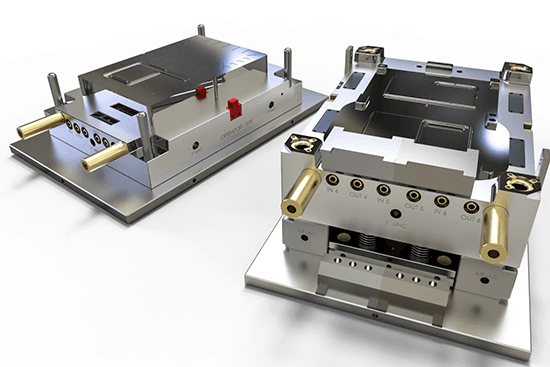

Injection Mold Tooling

Overmolding

Insert Molding

Liquid Silicone Rubber Molding Service

Plastic Engineering

Our plastic engineering and design services provide clients with creative ingenuity and highly skilled manufacturing and engineering expertise to achieve the speed to market they deserve. Our engineers work with you from conception to production and develop the ultimate process optimization for total project success.

- Product Development Services

- Design for Manufacturability/Assembly

- Prototype to Production Manufacturing

- Multiple Engineering Software

- Design Engineering

- Material Selection Assistance

- Tooling and Fixture Build

- Robotics and Automation

- Technological Innovation

- Mold Flow Analysis

- Assembly and Verification Testing

- Cost Savings ldeas/Recommendations

Ready to start your next project?

Whether you need rapid tooling prototyping or finished product production, Xtmachining has the skills and experience to guarantee excellent results. Contact us for a quote.

In-House Mold Manufacturing

All Xtmachining customer molds are manufactured in-house at our manufacturing facility. Our mold manufacturing area is staffed by experienced designers and machinists using state-of-the-art software and CNC machinery. Once the customer part design is finalized and approved for manufacturing, our team will design and build the plastic injection mold to your production requirements.

If your company needs to purchase new tooling for an injection molding project, you should want a single supplier that is responsible for the quality of both the injection mold and the production part. If your injection molding supplier does not manufacture their own tooling, you could face significant quality issues, delays in delivery times, and unforeseen costs in your budget. If you are an engineer or buyer responsible for finding a supplier for plastic injection molding parts, let us provide you with high-quality parts and tooling.

Mold Design Services

Our in-house mold design team employs state-of-the-art concepts and practices when creating custom products tailored to your company’s needs. We draw on our diverse backgrounds and unparalleled expertise when creating molds to your specifications. We also utilize advanced software solutions to guide us through the process and enable us to make informed decisions.

Our Engineering Team

Our experienced, knowledgeable, cross-functional team of engineers covers multiple disciplines to ensure we deliver the most comprehensive results. We take a collaborative approach when working with our customers to develop innovative concepts to ensure a robust, reliable, and efficient supply chain. Our engineers will bring these concepts to life through the creation of fully functional prototypes and production tooling processes. You can be assured that the products we ultimately develop will provide the right solution for your business.

Plastic Materials

We offer a wide variety of plastic materials to suit almost any application. If you don’t find the material you need, please consult us.

- Acetal (Acetal)

- Polycarbonate (PC)

- Polypropylene (PP)

- Acrylic (Acrylic)

- Polyester (Polyester)

- Polystyrene (PS)

- Acrylonitrile Butadiene Styrene (ABS)

- Polyether Imide (PEI)

- Polysulfone (PSU)

- Biodegradable Polymers (Biodeg Polymers)

- Polyetherketone (PEK)

- Polyurethane (PUR)

- Cellulose Acetate (CA)

- Polyethylene (PE)

- Polyvinyl Chloride (PVC)

- Polyamide (Nylon)

- Polyimide (PI)

- Styrene Acrylonitrile (SAN)

- Polyarylate (Polyarylate)

- Polyolefin (Polyolefin)

- Thermoplastic Elastomer (TPE)

- Polybutylene (PB)

- Polyphenylene Sulfide (PPS)

- Thermoplastic Polyurethane (TPU)

Surface finish of injection molding

The process includes various steps from injection mold processing to the entire plastic injection molding. Surface treatment of the mold is a process that is usually carried out during the production process. Our company performs specific surface treatment after injection molding according to customer requirements.

Glossy

SPI grade A1, A2 and A3 surface treatments are made with diamond polishing to achieve a smooth and shiny surface effect.

Semi-gloss

SPI standard B1, B2 and B3 grade surface treatments use sandpaper to produce a semi-gloss surface finish.

Matte

C1, C2 and C3 SPI grade surface treatments use grit sandstone to achieve a rough texture and uneven surface.

Textured

D1, D2 and D3 grade treatments use dry spray glass beads and oxides for surface treatment to produce a very rough and textured surface.

Want to start your injection mold project today?

We provide high-standard injection molding services, supporting small batch manufacturing, fast delivery and quick response within 24 hours.

What is the plastic injection molding process?

The plastic injection molding process uses a machine that is divided into a clamping unit and an injection unit. A metal mold containing a cavity that matches the desired part geometry is clamped to the machine. Next, the injection unit melts the plastic granules and injects the molten plastic into the mold at extremely high pressure. Depending on the characteristics of the part and the type of plastic, a holding period may be required during which the plastic-filled cavity needs to be under pressure to ensure that it is properly molded.

The mold has cooling channels that help to cool the material evenly. During the cooling period, the pressure is released to aid cooling. Finally, the clamping device is released and a mechanism ejects the part from the mold, triggering the process and then repeating. Injection molded parts may require additional finishing steps, such as removing molding aids such as plastic gates or runners, polishing, or assembly to other parts.

Advantages of Custom Plastic Injection Molding

As one of the most versatile methods of producing plastic parts, plastic injection molding offers numerous advantages over other plastic molding methods. Custom plastic injection molding is not only more straightforward and reliable than other methods, but it also offers the following advantages:

- High efficiency with fast production

- Complex part design with a high level of consistency

- Enhanced strength

- Flexibility of material and color options

- Reduced waste

- Lower labor costs over other types of molding

Partner, not just a manufacturer

At Xtmachining, we know that our customers are our reason for existence. We are nothing without you, and your business is our business. Building true partnerships with our customers allows us to gain a deep understanding of your business and its unique challenges. This understanding allows us to propose tailored solutions to meet your needs.

We work closely with you to identify opportunities to reduce costs and improve quality. When we design your part or mold, we do so based on a thorough understanding of the manufacturing process: from the injection molding cycle to cost and cycle time targets. While every project is different, our proven processes and standards help us consistently achieve the best results for our customers across all industries. Partner with us today and experience the Xtmachining difference.

Industries We Serve

We are able to work with many different customers across a wide range of industries to build molds to their specifications as well as mass produce plastic products. Learn how to truly help our customers succeed in their market competition.

Ready to start your next project?

You can trust us to handle projects of all sizes and complexities.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving…