Rapid Prototyping

Are you looking for ways to accelerate your new product development process? Looking for a manufacturing partner that can provide design and engineering, production and manufacturing services to help you get your products to market faster? Xtmachining can help you quickly iterate part designs using rapid prototyping to accelerate your new product development.

Rapid Prototyping Services Complete Part Designs

Have a product design, idea, or invention? With our rapid prototyping and manufacturing services, you can turn your concept into reality!

As your rapid prototyping company, our services span the entire process from the beginning of product design to full manufacturing. We are a prototype parts manufacturer with the capabilities and expertise to help you at every step of the development process.

From concept modeling to functional prototypes

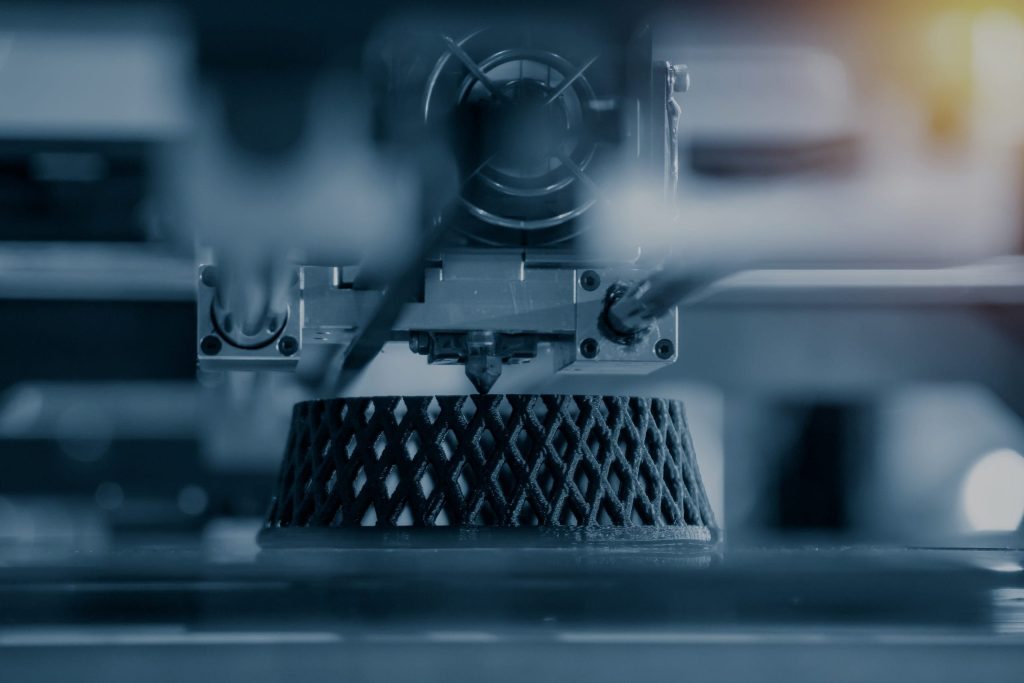

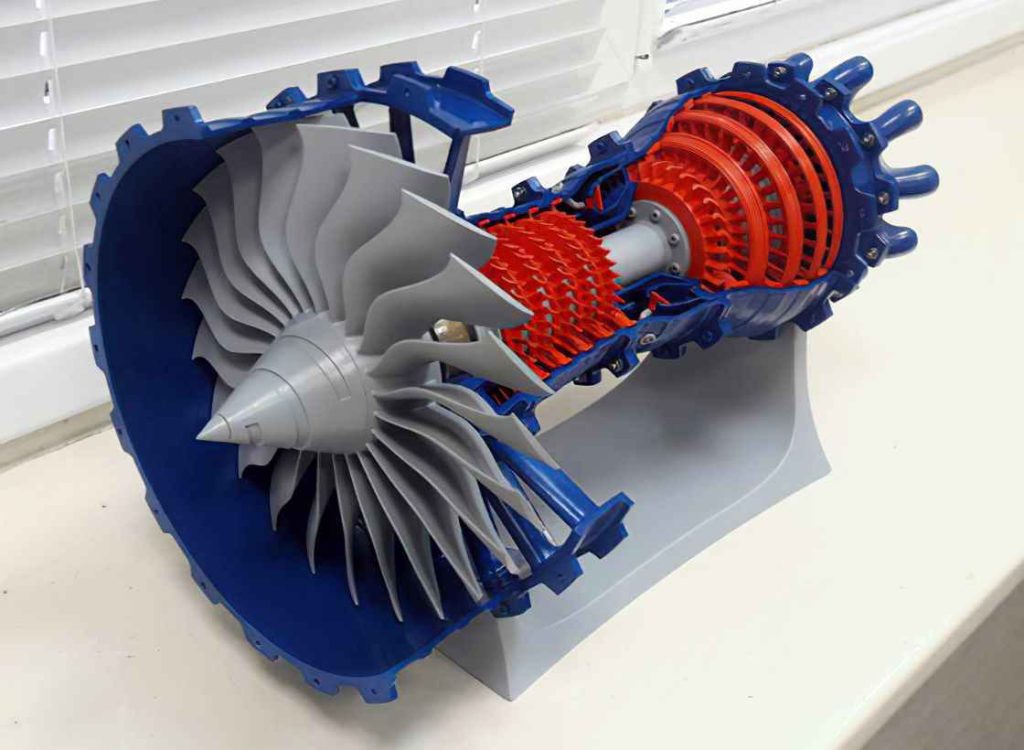

Experience transforming concepts into models faster than ever before with cutting-edge additive manufacturing technology. And experience greater flexibility, accuracy, and cost savings at every stage of the product development lifecycle, more reliable and efficient than traditional methods. With a complete end-to-end solution portfolio, including hardware, software, high-performance materials, and services. Advanced prototyping produces higher quality results while reducing costs and time to market. As a company that provides best-in-class rapid prototyping solutions, we also use 3D printing to open up unlimited possibilities for conceptualization, design, and final production.

Product Design and Rapid Prototyping Manufacturing

Rapid prototyping has become an integral part of product design, enabling the rapid transformation of digital concepts into tangible models. This rapid realization facilitates instant feedback, helps identify potential design flaws, and ensures a smoother transition from ideation to production.

Xtmachining is committed to providing customers with effective prototype part selection. Our on-site prototyping facilities are designed to meet engineering build needs. Our integrated testing, quality, and procurement teams ensure that each product prototype meets your strict standards. Coupled with our connections with global suppliers, our customers can enjoy the advantages of one-stop contact and preferential prices.

And we have expanded the range of quality parts for prototyping and adapted them with new features and functions of the latest technology. In addition, our integrated testing, quality, and procurement teams ensure that each prototype meets your strict standards. We will strive to provide you with fast and accurate concept expression, with a variety of methods that suit your time and budget to satisfy you.

As a company that provides comprehensive rapid prototyping solutions, we integrate CAD design with the functions of 3D printing, CNC machining, and more processes. Simplifying the entire process from design to production, making it the best choice for companies that want to fully utilize the potential of rapid prototyping in the manufacturing industry.

Start your project now

Xtmachining is your go-to provider of product development services. From the design stage to prototyping to manufacturing, you can count on our team to provide outstanding solutions to turn your next big idea into reality.

Rapid Prototyping Process Types

Our experience and team that is well versed in various rapid prototyping processes can ensure your rapid prototyping manufacturing and assist you in optimizing your prototype design, selecting the right process to reduce costs, and achieving rapid mass production. We help you test various materials and finishes so that you can make an informed decision on how to move forward with your project. Xtmachining offers a range of rapid prototyping processes for you to choose from.

3D Printing

CNC Machining

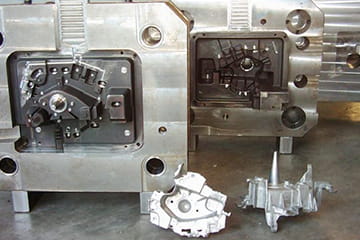

Injection Molding

Sheet Metal Fabrication

Vacuum Casting

Die Casting

Rapid Prototyping Applications

Because of its utility and versatility, rapid prototyping has been widely adopted for these and other common applications:

- Visual prototypes and concept models

- Functional prototypes

- Pre-production prototypes

- Validate form, fit and function prior to production of tooling

- Test jigs and fixtures for accuracy

- Building molds for prototypes

- Marketing mockups for trade shows

Material Options for Rapid Prototyping

We handle all types of materials including metals, many types of thermoplastics, elastomers, etc. We help our customers select and purchase the right type of material for their application needs.

Metals

- Aluminum

- Stainless Steel

- Tool Steel

- Alloy Steel

- Brass

- Copper

- Titanium

- Mild Steel

- Invar

- Inconel

Plastics

- ABS

- Polypropylene

- POM

- Acaylic

- PEEK

- Polycarbonate

- Nylon

- Polyethylene

- PVC

- PET

- PTFE

- PA+GF30

- HDPE

- PEI(Ultem)

- PMMA

Choose the right post-processing for your prototype parts

Xtmachining can provide the best rapid prototype post-processing, including hand finishing, grinding, sandblasting, polishing, painting and printing. In addition, we also provide a variety of special surface treatments, including laser etching, anodizing, powder coating, metal plating, vacuum metallization, chromating, chemical finishing, passivation, heat treatment, etc.

Request a Quote for Prototyping & Manufacturing Services

Are you ready to start your next project? Send us details or a CAD file today for a competitive quote.

What is Rapid Prototyping?

Rapid prototyping is a product development method that utilizes turnkey manufacturing techniques to quickly produce multiple iterations of components for testing and evaluation. It is a method of manufacturing parts as quickly as possible for real-world inspection. Rapid prototyping is an important stage in the part and product development process. By utilizing fast and affordable manufacturing methods, multiple iterations of a part or product can be easily produced for testing and analysis.

In terms of rapid prototyping strategies, engineers often need to manufacture multiple prototypes at the same time, or quickly produce and modify one prototype until the prototype meets the intended specifications. Rapid prototyping provides engineers with key data points to help them decide on any design modifications before generating more expensive models for further analysis or final production. In this sense, rapid prototyping reduces the risk of rushing into production without sufficient quantity of confirmed data.

Rapid prototyping services have a variety of viable manufacturing processes to choose from. While there are many different options in terms of which rapid prototyping process to use, engineers must decide which process and material will work best for their specific prototype. A growing trend in rapid prototyping is the use of 3D printing technologies, as these methods are very affordable and have a short lead time.

Advantages of Rapid Prototyping

Rapid prototyping offers significant advantages to part designers. You can use it to:

- Reduce design and development time

- Create a physical model to solicit customer feedback

- Validate product design assumptions, including form, fit, and function

- Eliminate production tooling, saving time and money

- Identify and reduce product design flaws before production

- Speed up time to product launch

Start your rapid prototyping process now

Prototyping is an essential step in product development. You need to evaluate the design and functionality of your product before moving on to the more costly step of production. Great rapid prototyping technology is just what you need! Rapid prototyping technology enables engineers and designers to manufacture and test their products faster and iterate as needed. Whether creating scale models of physical parts to verify form or visual effects, trying out assemblies, or building functional features and testing them, rapid prototyping technology can help you achieve your goals in a timely manner. There are also new manufacturing technologies that will change the way prototypes are produced, such as additive manufacturing, which allows you to create high-fidelity prototypes with excellent surface finish. Additive manufacturing can not only promote the growth of your company, but also speed up prototyping. Learn how you can benefit from a more scalable, flexible and resilient prototyping and production manufacturing process.

Industries We Serve

Our dedicated engineering team provides custom solutions to a wide range of industries, utilizing innovative technologies and design strategies to deliver optimal results for our clients.

Start making your prototype today

Click the button below to submit relevant part drawings, 3D files and other information. We will ensure prompt processing and ensure you receive a quote as soon as possible.

What’s Precision Machining? Process, Advantage, and Applications

Our world is surrounded by complex technology evolving at a rapid rate. In everyday life, we see a lot of intricate parts, such as gears and components inside machinery, which makes one wonder what goes into manufacturing them. Well, for most of these products and to the question of how they are made, the answer […]